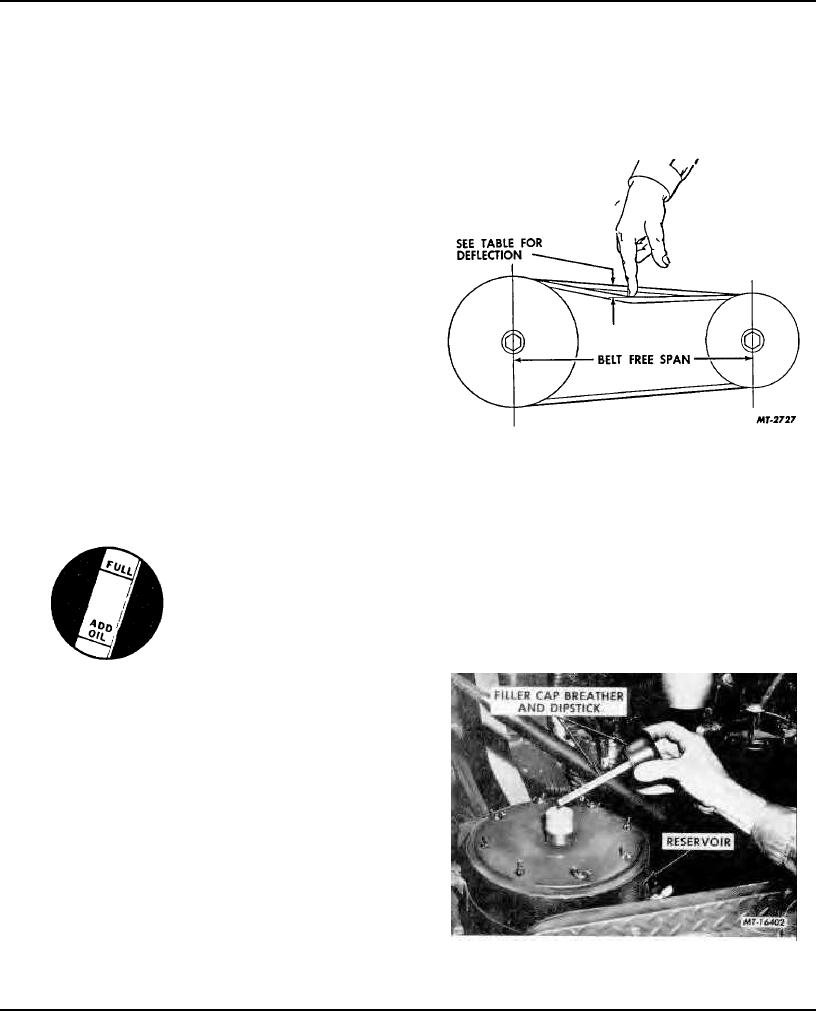

FAN BELT ADJUSTMENT

MAINTENANCE

Always sho-ten distance between pulley centers so

the belt can be installed without force.

2. Separate screen retainer and magnet. On some

units magnet and screen are one integral unit. Magnet

NOTE: REPLACE BELTS IN COMPLETE SETS

action in filter screen will remove any metal particles that

may enter fuel system.

Tighten fan belts so that the pressure of the index

finger will depress as shown.

3. Clean screen and magnet in cleaning solvent

and dry with compressed air.

4. Reassemble magnet in screen. Install filter

screen assembly in fuel pump with hole down.

5. Replace spring on top of filter screen assembly.

6. Replace cap; tighten to 20/25 foot pounds.

IMPORTANCE OF PROPER OIL

OIL CHECK PROCEDURE

LEVEL

Before checking the oil level, clean

Since the transmission oil cools,

around the end of the fill pipe before

lubricates and transmits power, it is

important that the proper oil level be

removing the dipstick. Dirt or foreign

matter must not be permitted to enter

maintained at all times. If the level is

the oil system because it can cause

too low, the converter and clutches will

not receive an adequate supply. This

valves to stick, cause undue wear of

can result in poor performance or

transmission parts or clog passages.

Check the oil level by the following

transmission failure. If the level is too

procedure:

high, the oil will foam, causing the

FAN BELT TENSION

transmission to overheat. Check the

DEFLECTION

oil level at intervals specified in your

1.

Operate the transmission in a

BELT WIDTH

PER FT. OF SPAN

vehicle service instructions, or more

drive range until normal

frequently, if operating conditions

operating temperature (160-

indicate. Report any abnormal oil level

220F) is reached.

1/2"

13/32"

to your maintenance personnel.

11/16"

13/32"

2.

Shift through all drive ranges

to fill the clutches and oil

3/4"

7/16"

passages.

7/8"

1/2"

3.

Park the vehicle on a level

1"

9/16"

spot, shift to neutral (N) and

apply the parking brake. Let

POWER STEERING PUMP OIL RESERVOIR

the engine run at idle speed.

4.

Check the oil level after

wiping the dipstick clean.

The oil level in the reservoir must be maintained to

The safe operating level is

the "F" mark on the dipstick type indicator attached to

between the FULL and ADD

the filler cap.

marks on the dipstick.

OIL SPECIFICATIONS

5.

If not within this range, add or

drain oil as necessary to

Only Dexron automatic transmission

bring the level to the FULL

fluid is recommended.

When the

mark.

ambient temperature is below - 10F,

an auxiliary preheat is required. Raise

HOW

TO

KEEP

LITTLE

the temperature above -10F before PROBLEMS FROM BECOMING

operating the transmission.

BIG PROBLEMS

KEEP OIL CLEAN

By observing the operation of the

transmission and making a few

It is absolutely necessary that the oil

periodic checks, minor mechanical

put into the transmission be clean. Oil

problems can be kept from becoming

must be handled in clean containers,

major overhaul.

fillers, etc to prevent foreign material

from entering the transmission.

If one of these conditions occur-

CAUTION: Containers that have been

Shifting feels odd.

used for anti-freeze (ethylene glycol)

should not be used for oil going into

Transmission automatically up-

any machinery.

shifts or downshifts at irregular

intervals.

Notify your

vehicle

maintenance

personnel.

MT17877

18