OPERATION

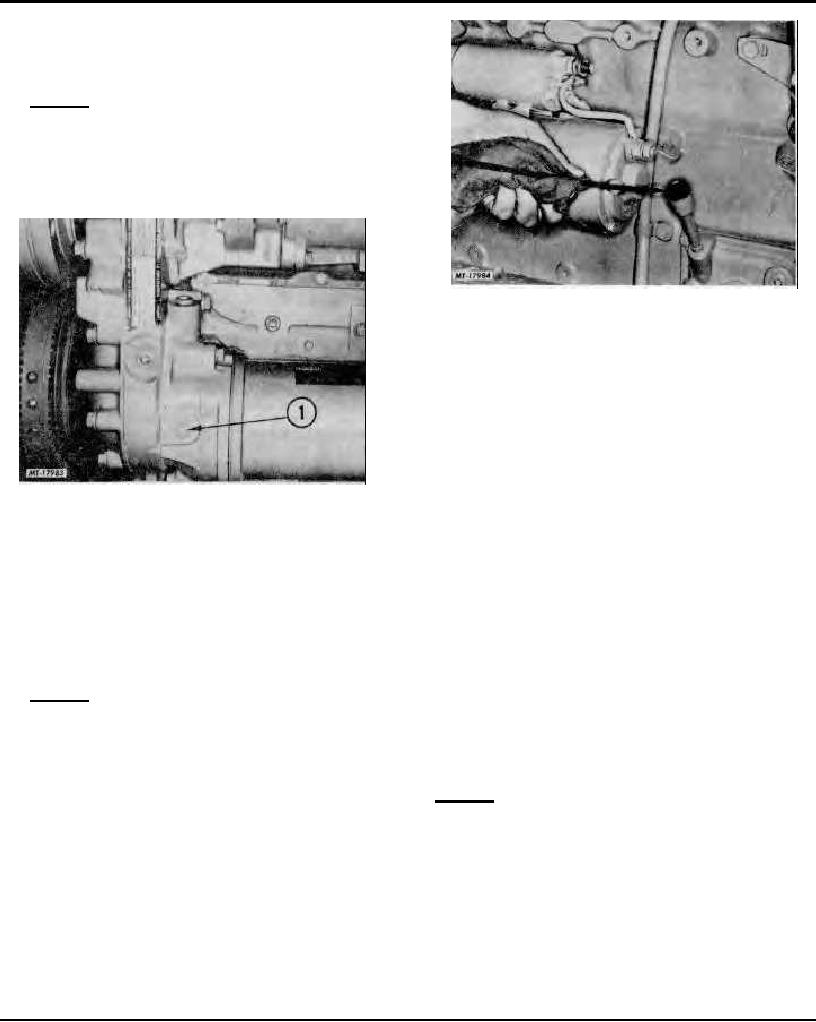

2. Remove plug from head of lubricating oil filter

housing (Fig's. 1-1 and 1-2) or filter can to prime

system.

Caution: Do not prime engine lubricating system

from by-pass filter.

3. Connect a hand-or motor-driven priming pump

line from source of clean lubricating oil to plug boss in

housing.

CHECK AIR CONNECTIONS

Check air connections to compressor and air

equipment, as used, and to air cleaners and air

crossovers to assure all are secured.

CHECK ENGINE COOLANT SUPPLY

1. Remove radiator cap and check engine coolant

supply. Add coolant as needed to completely fill system.

See Section 3 for coolant specifications.

2. Make visual check for leaks and open water filter

4. Prime until a 30 psi (2.1 kg/sq cm) minimum

shut-off valves.

pressure is obtained.

5. Crank engine at least 15 seconds (with fuel

STARTING THE ENGINE

shut-off valve closed or disconnected to prevent

starting), while maintaining external oil pressure at a

Starting requires only that clean air and fuel be

minimum of 15 psi (1.1 kg/sq cm).

supplied to the combustion chamber in proper quantities

6. Remove external oil supply and replace plug in

at the correct time.

lubricating oil filter housing, torque 15 to 20 ft-lbs (2.1 to

2.8 kg m).

NORMAL STARTING PROCEDURE

Caution: Clean area of any lubricating oil spilled

If fuel system is equipped with overspeed stop, push

while priming or filling crankcase.

"Reset" button before attempting to start engine.

7. Fill crankcase to "H" (high) mark on dipstick with

1. Set throttle for idle speed.

oil meeting specifications, listed in Section 3. No change

in oil viscosity or type is needed for new or newly rebuilt

Caution: Protect the turbocharger during the start-

engines.

up by not opening throttle or accelerating above

1000 RPM until normal engine idle speed oil

A dipstick oil gauge is located on the side of the

pressure registers on gauge.

engine. Fig. 1-3. The dipstick has an "H" (high) (1) and

"L" (low) (2) level mark to indicate lubricating oil supply.

2. Disengage driven unit or make sure gears are in

The dipstick must be kept with the oil pan, or engine,

neutral.

with which it was originally supplied. Cummins oil pans

3. Open manual fuel shut-down valve, if engine is

differ in capacity with different type installations and oil

so equipped. Electric shut-down valves operate as

pan part numbers.

switch is turned on.

33