TRUCK SERVICE MANUAL

BRAKES-AIR

Only test gauges known to be accurate are to be

used for checking brake valve delivery pressures,

governor pressure settings and other tests. Test gauges

differ from ordinary dash gauges in respect to material

and workmanship. Due to these differences they are

more accurate over entire range and maintain their

accuracy over longer periods.

After initial starting of engine, if air gauge shows

that one circuit has no air pressure nor a noticeable

increase in air pressure within a reasonable length of

Fig. 4 Exterior View of Low Pressure Indicator

time (30 to 60 seconds) and the low pressure switch and

low pressure light will not shut off, this indicates an open

OPERATION (Fig. 5)

drain cock or a failure in the brake system.

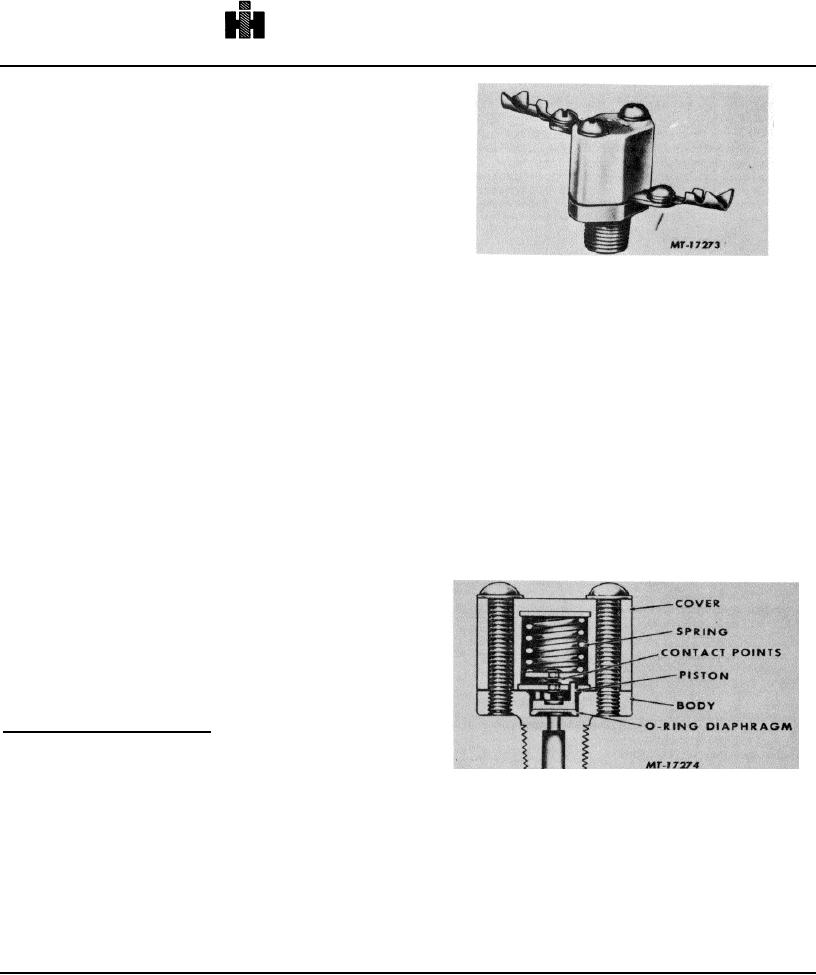

To describe the operation, we shall assume the

NOTE: It is not compulsory but it is advisable that

Low Pressure Indicator is set for 70 psi. Setting of

vehicles be inspected to be sure that the air gauges

indicator is marked on a label on valve body. When air

are properly connected. The primary system should

pressure at supply port and under the diaphragm is

be connected to the green needle and secondary

above 70 psi, electrical contacts remain open because

system to red needle. This can easily be checked by

the force exerted by air pressure underneath the

charging the air system, bleeding off the primary

diaphragm overcomes force exerted by the spring above

system (rear brake reservoir) and the green needle

the diaphragm.

should drop. If the green needle does not drop the

When air pressure below the diaphragm drops

air lines on the gauge should be changed. Al

below 70 psi, the spring exerts a force which is greater

chassis would be assured that they are connected in

than the force exerted by the air pressure below the

the same manner and identification of both systems

diaphragm. This causes the piston to move and allow

will be uniform.

the electrical contacts to close. This completes or closes

electrical circuit to warning device, warning driver of low

SERVICE CHECKS

air pressure in the system .

1. Check the air gauge for accuracy. The simplest way

to do this is to compare the pressures registered by the

gauge over its normal pressure range with the pressure

registered by a test gauge know to be accurate.

2. A gauge which loses its accuracy must be replaced.

The continued use of a dash gauge showing an error of

more than 5 pounds is not recommended.

LOW PRESSURE INDICATOR (LP3 Type)

DESCRIPTION

The low pressure indicator (Fig. 4) is a safety

device designed to give an automatic warning whenever

Fig. 5

Cross Sectional View of Low Pressure Indicator

the air pressure in the primary or secondary air brake

system is below approximately 70 pounds. Operating as

MAINTENANCE

an air controlled switch of an electrical circuit, the low

Once a month or after 10,000 miles, check

pressure indicator automatically sounds a buzzer when

electrical connections.

the air pressure drops too low. The warning will be both

Every year or 100,000 miles, perform SERVICE

visible (light) and audible (buzzer).

CHECKS. If diaphragm is ruptured, replace complete

The nominal pressure setting of 70 pounds is

assembly.

subject to a tolerance of plus or minus 6 pounds so that

the actual operating pressure of the low pressure

indicator may vary between 76 pounds maximum and 64

pounds minimum.

144