ELECTRICAL

MOTOR TRUCK SERVICE MANUAL

Installation of Battery

Only a fully charged battery can deliver the published

and guaranteed performance which is the basis of the

sale. The best assurance against trouble and costly

service is to make certain that batteries sold to

customers are fully charged when installed.

Each battery must be coded indicating the month

and year it was installed.

The battery should rest level in the cradle and be

fastened securely in place by suitable hold-downs, using

care to tighten evenly from each end a little at a time so

as not to distort or break the container. Do not draw the

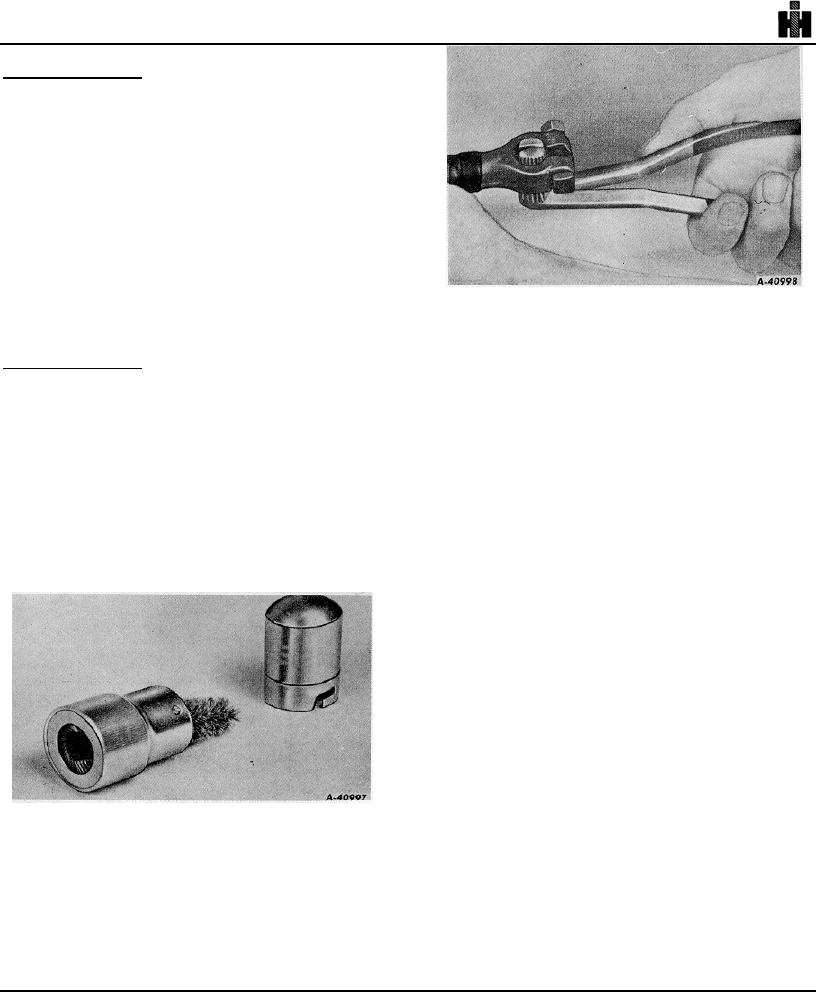

Fig. 17 Spreading Cable Clamp with Terminal Spreader

hold-downs too tight.

Apply a thin film of chassis lube to inside of clamp

Installation of Cables

terminals and over bolt stud before reconnecting

terminal. Connect ground terminal last. Tighten the

Cables must be of sufficient length to reach terminal

terminal bolts, being careful to position the clamp

posts without causing undue strain on cover or terminals.

terminals and cables so as not to interfere with the filler

Note that tapered positive terminal of the battery is 1/16

caps or rub on the hold-down parts.

inch larger at the top than the negative terminal and the

opening of the positive cable clamp is correspondingly

Before cranking the engine, turn on the lights and

larger to fit it. Always clean the battery terminal parts

make certain the ammeter indicator shows discharge.

and the inside of the clamps bright with sandpaper or

This will indicate correct battery installation.

special terminal cleaner, Fig. 16. Cleaning the clamp

Considerable damage to the electrical system can result

terminals and tapered posts each time they are

if a battery is installed incorrectly.

reconnected is very important in voltage-regulated

systems.

When making replacement of original battery cables,

starting motor cables or other wires utilizing protective

loom or grommets, it is essential that the service cable

be equipped with the same type loom or grommet

protection as was removed on the replaced cable or

wire. Cables that are replaced without proper loom

protection create a fire hazard. The wiring circuits on

new vehicles are closely checked and approved by

Underwriter Companies; therefore, the original circuits

should be maintained both as to location and protective

devices.

The loom or grommet is placed on cables for

safeguarding against chafing or cutting through the

insulation at points where cables contact chassis.

Fig. 16 Combination of Brushes for Cleaning Terminals

When replacing cables on customers' trucks or when

and Cable Clamps

making sales of cables, make certain that a protective

loom or proper grommets are provided where required.

Care should be taken when installing a cable

terminal. It should never be hammered into place. To

The storage battery can deliver only what the battery

do so may crack battery cover seal. Also some metal

cables are able to carry to the electrical system. The

may be sheared from post, making it too small for good

battery cannot operate efficiently if it has to overcome the

contact when the next replacement is necessary. The

best practice is to pry jaws of terminal apart or use a

clamp spreader, Fig. 17, before slipping it over the post.

268