TRUCK SERVICE MANUAL

ENGINE

Vehicle Braking Group 20

2. Install special locking plates on two studs

COMPRESSION BRAKE

located in center of each housing. Tighten nuts to 55 to

60 ft-lb. [7.6 to 8.3 kg m] torque in sequence as shown in

Jacobs Brake (Compression)

Fig. 14-9.

3. Bend long tab of each special locking plate down

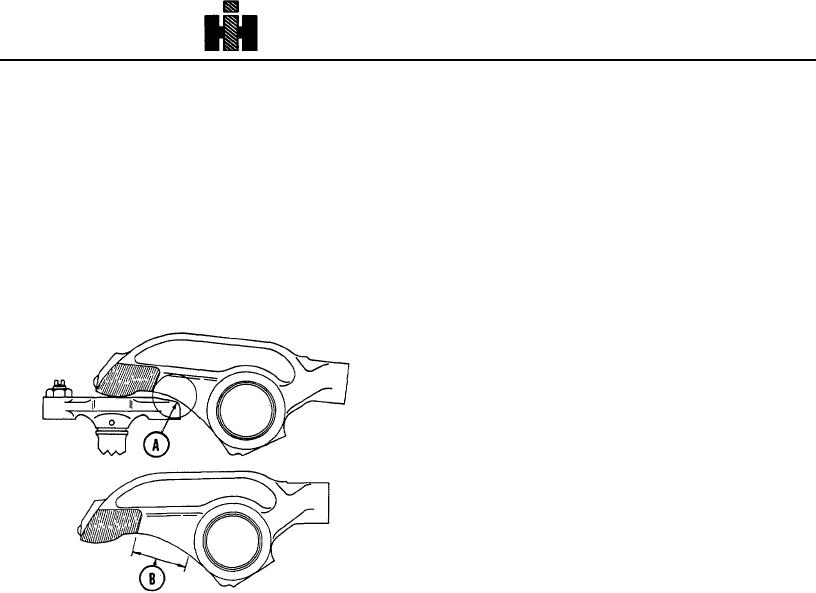

CHECK CROSSHEAD.TO ROCKER LEVER

over housing surface, bend one short tab up against flat

CLEARANCE

of each hex nut.

Barr engine in direction of rotation until valves are closed

Slave Piston Adjustment Procedure

on each cylinder as checked through firing order, hold

lever in contact with Jacobs Brake crosshead and check

Loosen and back off locknut, Insert socket head wrench

interference between crosshead and lever, clearance

and back slave piston adjusting screw out of housing

must be as shown in Fig. 202 (A). If feeler gauge will

until slave piston seats in it's bore.

not pass

Slave piston adjustment must be made with the engine

stopped (warm or cold) and the exhaust valves closed.

Bar the engine in direction of rotation until "A" or "16

V.S." mark on accessory drive pulley lines up with the

timing mark on the gear case cover. With the engine in

this position, the exhaust valves of cylinders 16 are

closed.

Insert a 0.18" feeler gauge between the slave piston and

the crosshead, turn the adjusting screw in until a slight

drag is felt on the feeler gauge. Continue turning engine

in direction of rotation and set slave piston clearance on

cylinders 25 and 34.

To bleed brake units for immediate operation, manually

depress solenoid armature five or six times in

succession with engine running to permit oil to fill

passages in housing.

A. 0.060 Inch [1.524 mm] Clearance

Attach electrical harness to terminal in Engine Brake

B. Grind Area

housing.

Fig. 20-2. (N12045 J). Clearance area between lever and

Mount fuel pump switch and actuating arm using

crosshead

capscrews on fuel pump to secure switch.

through area, remove rocker lever and grind sufficient

Actuating arm may be bent or relocated to contact switch

clearance in area (B), grinding must cover complete area

when throttle lever is in idle position.

in a continuous arc. Grind smooth all sharp edges.

Adjustment

INSTALLATION

Adjust screw in actuating. arm so that audible "click" is

heard when throttle arm moves to an idle fuel position.

1. Install new gaskets and Jacobs Brake units to

rocker housings.

Note: Check PT Fuel Pump throttle shaft to insure that

throttle pedal will move throttle shaft to full fuel position

Note: If studs were removed from rocker housings,

after

installing

the

actuating

arm.

replace and tighten to 65 to 75 ft-lb. [9.0 to 10.4 kg m]

torque in sequence as shown in Fig. 14-9.

436