TRUCK SERVICE MANUAL

WHEELS, RIMS, AND TIRES

factory performance from oil seals, the following

information has been prepared to guide and assist in

proper installation.

Due to the various types of front and rear axle hub

seal installations, check axle ring and hub seal position at

time of disassembly to assure proper reassembly of new

seal and axle ring (wiper).

OIL SEALS WITH AXLE RING (WIPER)

Axle Ring (Wiper) Installation

1. Thoroughly clean all parts: axle tube or spindle,

bearings, nuts and inside of wheel hub.

2. Remove burrs from axle tube or spindle

shoulder. Shoulder must be smooth.

3. Apply a thin coat of Permatex No. 2 to inside

perimeter of axle ring.

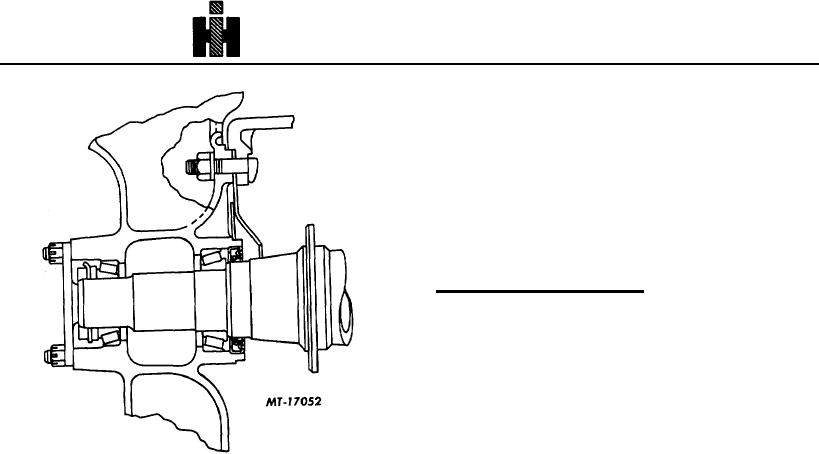

Fig. 4. Medium Duty

4. Place axle ring on axle tube or spindle using an

installing tool (Fig. 5).

REAR WHEEL BEARINGS

NOTE : A suitable installing tool can be

Full Floating axle wheel bearings (Fig. 3 and Fig. 4)

made locally by obtaining a piece of

are adjusted by an adjusting (inner) nut on end of axle.

standard 8.9 cm (3-1/2") inside diameter

Install adjusting nut and rotate wheel while tightening to

tubing approximately 25.4 cm (10") long.

be sure bearings are properly seated.

Weld a used close fitting bearing cone or large washer to

NOTE : 68.0 N.m (50 ft lbs) torque on

one end and similarly close opposite end with a plate.

adjusting nut is considered sufficient to

This will enable tool to pilot squarely onto axle tube and

seat bearings.

permit driving force to be centered over the complete

ring. The same type of tool can be used for both front

Back off adjusting nut 1/4 turn and install lockwasher

and rear axles.

and jam nut. Tighten jam nut to 203 N.m (150 ft lbs)

torque and bend over lockwasher tang to secure nut.

The care with which the axle ring is installed cannot be

Assemblies which use doweled adjusting nut and pierced

over-emphasized. Damage to this ring will result in

wheel bearing nut lock require 271 407 N.m (200 300 ft

shortened seal life.

lbs) torque on outer lock nut.

5. Tap on end of axle tool driving axle ring firmly on

OIL SEALS (OIL LUBRICATED WHEEL BEARINGS)

shoulder until axle tool contacts shoulder.

Remove excess Permatex.

Various precautions are necessary when oil seals

are installed in wheels and also when wheels with oil

6. Check position of axle ring to make sure edge of

seals are installed on axles. To insure

ring is parallel with shoulder.

846