TM 5-3805-254-20-1

ORGANIZATIONAL TROUBLESHOOTING - CONTINUED

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

AIR SYSTEM AND BRAKES

60. AIR HORN DOES NOT WORK.

WARNING

Safety goggles must be worn when working with air lines to prevent personal

injury.

NOTE

Check AIR PRESSURE gage for air pressure between 90 and 130 psi. If specified

air pressure is not present, start engine and check that air pressure in air system is

between 90 and 130 psi (TM 5-3805-254-10). Shut down engine (TM 5-3805-254-10).

Step 1.

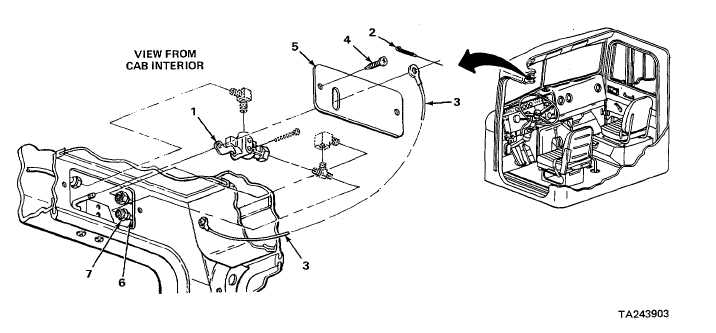

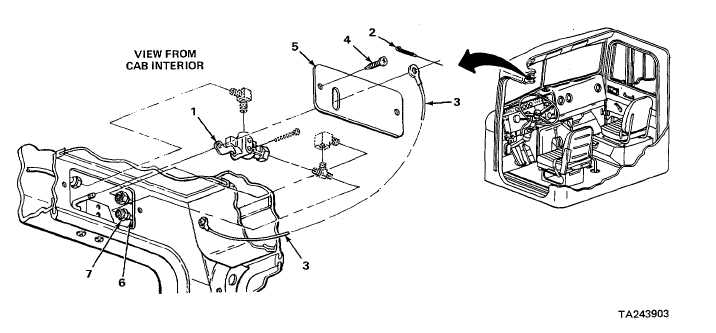

Check for air pressure at valve (1) as follows: Using 6-inch slip-joint pliers, take out cotter pin (2),

and pull chain (3). Using number one cross-tip screwdriver, unscrew and take out two screws (4),

and take off cover (5). Using 5/8inch open-end wrench, loosen input hose fitting (6) six turns.

Listen for air pressure hissing at input hose fitting (7).

a. If air pressure is not present at input hose fitting (7), go to step 2.

b. If air pressure is present at input hose fitting (7), tighten hose fitting (7) using 5/8-inch

open-end wrench, and go to step 3.

2-326