TM 5-3805-254-20-1

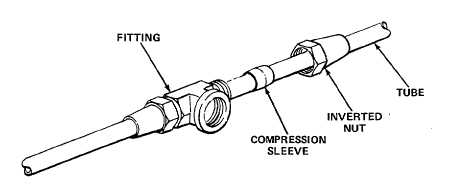

TUBES WITH COMPRESSION FITTINGS - CONTINUED

Install assembled tubes as follows:

1.

Insert end of tube, as far as it will go, into fitting to which tube is being installed.

2.

Screw inverted nut into fitting and tighten it against compression sleeve using open-end wrench. Compression

sleeve will clamp down around tube and conform to internal surface of fitting and inverted nut.

3.

Repeat steps 1 and 2 for other end of tube if needed.

AIR SYSTEM LEAK CHECK

If air system leakage is suspected, check suspected components as follows:

1.

Make sure that components are under air pressure by having an assistant operate them (TM 53805-254-10). For

example, if you suspect a leak in brake parts, have assistant step on brake treadle with air system fully charged.

2.

Coat suspected parts with solution of soap and water.

3.

Air valve exhaust parts may produce up to a 1-inch (2.5 cm) bubble in 1 minute. If soap solution foams or makes

a bubble faster, replace valve.

4.

Air line connections and air chambers should not leak at all. Any bubbling of soap solution is cause to repair or

replace connection or air chamber.

FLUID DISPOSAL

Get rid of contaminated drained fluids in accordance with your unit’s Standard Operating Procedures (SOP)

TA243981

2-432