TM 5-3805-264-14&P

Table 2-1. Operator Preventive Maintenance Checks and Services (PMCS) for M917A1 and M917A1

w/MCS Body (Con’t).

Item

No.

Interval

1

Before

FRONT

AND LEFT

SIDE

Overall

View

INSIDE CAB

Check under vehicle for evidence of

hydraulic fluid leakage.

Check that crank handle is stowed in

2

Before

Cargo

Cover

storage pouch in BII box.

Crank Han-

dle

3

Before

Startup

Location

Item To

Check/

Service

Procedure

4

During

Dump

Body Con-

trols and

Indicators

NOTE

Dump truck’s chassis air system con-

trols both models’ tailgate locking

mechanism and supplies air to the

M917A1 w/MCS tailgate.

a. Start engine and fully pressurize air

system (TM 9-2320-363-10).

b. Listen for air leaks on chassis and at

rear of dump body.

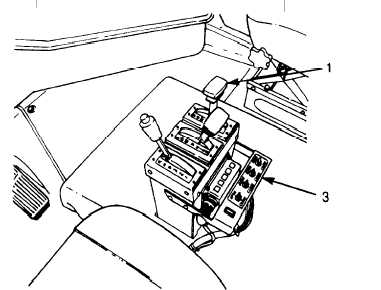

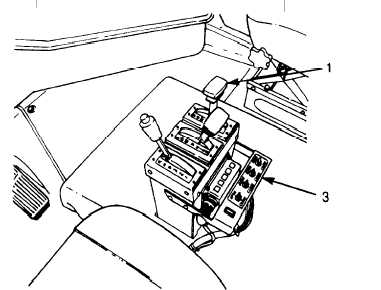

a. Check hydraulic control lever (1) and

MCS control unit (3) (M917A1 w/

MCS) for proper operation.

Not Fully Mission

Capable If:

Class III hydraulic fluid leaks are

evident.

b. Air leakage is evident.

a. Hydraulic control lever mal-

functions. MCS control unit

malfunctions and is required

for mission.

2-10