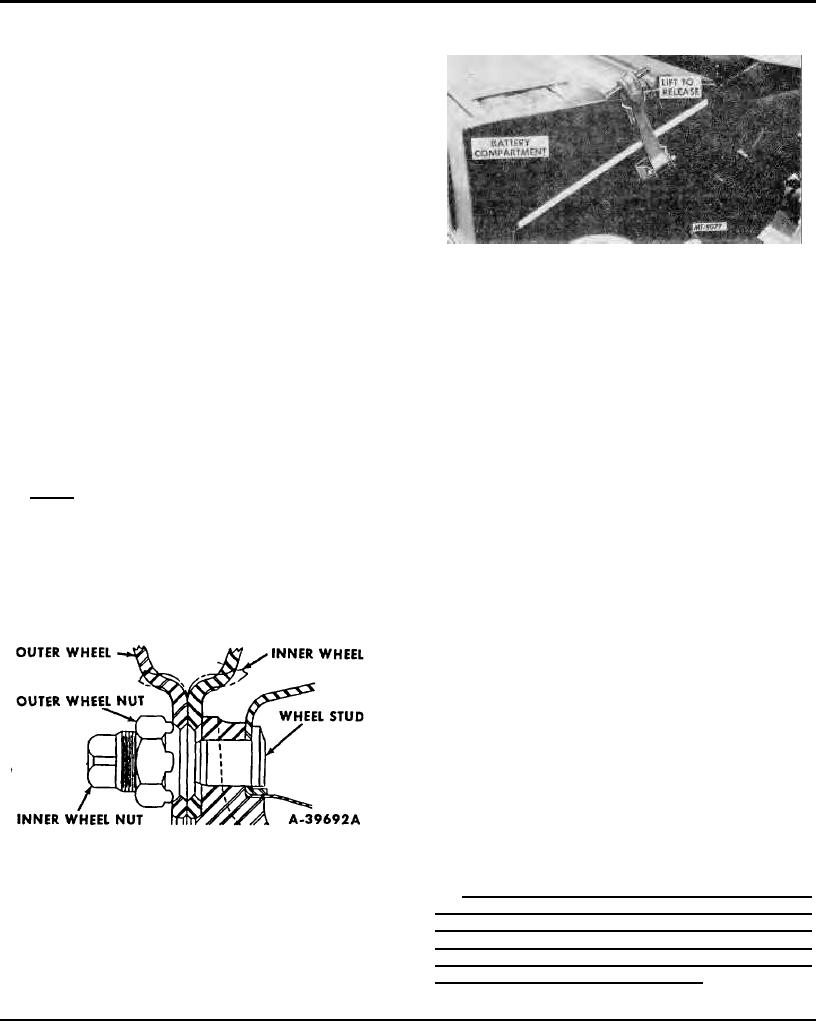

BATTERY

MAINTENANCE

camber, and axle caster.

WHEEL AND RIM MOUNTING NUTS

Disc Wheels

1. Mounting faces of the hub, wheel, and nut must

be free from dirt or excess paint. Mounting faces which

have been damaged from wear or abuse must be

repaired or replaced.

2. Right hand threads are used on the right side of

the vehicle and left hand threads on the left side.

Keep the batteries fully charged and check the

solution level at least every 15 days during hot weather

and 30 days in cold weather.

3. Tighten the wheel nuts alternately.

The solution in each cell should be 3/8" above the

4. Tighten the single wheel mounting stud nuts to

separator plates, or to the indicator level. When the

450-500 foot pounds torque.

solution is below this level, add distilled water, using a

clean syringe. Acid or electrolyte should never be added

5. On dual wheels loosen the outer nuts before

except by skilled battery personnel.

attempting to tighten the inner nuts. Tighten inner nuts

to 500 feet pounds torque and outer nuts to 450 foot

Under no circumstances should any special battery

pounds torque.

"dopes", solution, or powders be added to batteries.

NOTE: Always tighten the inner nuts 50 foot

Test the specific gravity of the electrolyte in each cell

pounds more than the outer nuts and never let the

with a hydrometer at least once a month. A hydrometer

outer nuts get below 400 foot pounds.

reading of 1.260 at 80 degrees F. indicates a full

charge. Never allow the battery to fall below 1.225

It is good practice to repeatedly (daily) tighten the

which indicates half charged. A discharged battery will

wheel nuts during the first 500 miles of service on new

freeze at 20 degrees F. above zero. A fully charged

trucks and any time the wheels have been removed.

battery will withstand temperatures as low as 80 degrees

Regular inspection periods should be established to

F. below zero.

assure keeping the nuts tight.

Battery cable terminals must be clean and tight.

Use hot water and common baking soda for removing

terminal corrosion and for cleaning the top of the battery.

Brighten the contact surface with steel wool, apply a light

coat of vaseline or chassis lubricant, and reassemble.

Be sure the terminals are clamped tightly and that the

battery is clamped securely in the battery box.

When working around the terminals and batteries

use extra care to avoid shorting. A good practice is to

insulate pliers and screwdrivers used with this system.

DO NOT CHECK BATTERY CONDITION BY

SHORTING (FLASHING) ACROSS TERMINALS.

CAUTION: Hydrogen gas is produced in the

normal operation of the battery.

Therefore, to

prevent a fire or dangerous explosion, it is

imperative that flames or sparks (that could be

caused by the use of jumper cables) be kept away

from the vent openings of the battery.

25