MOTOR TRUCK SERVICE MANUAL

AXLES-REAR I

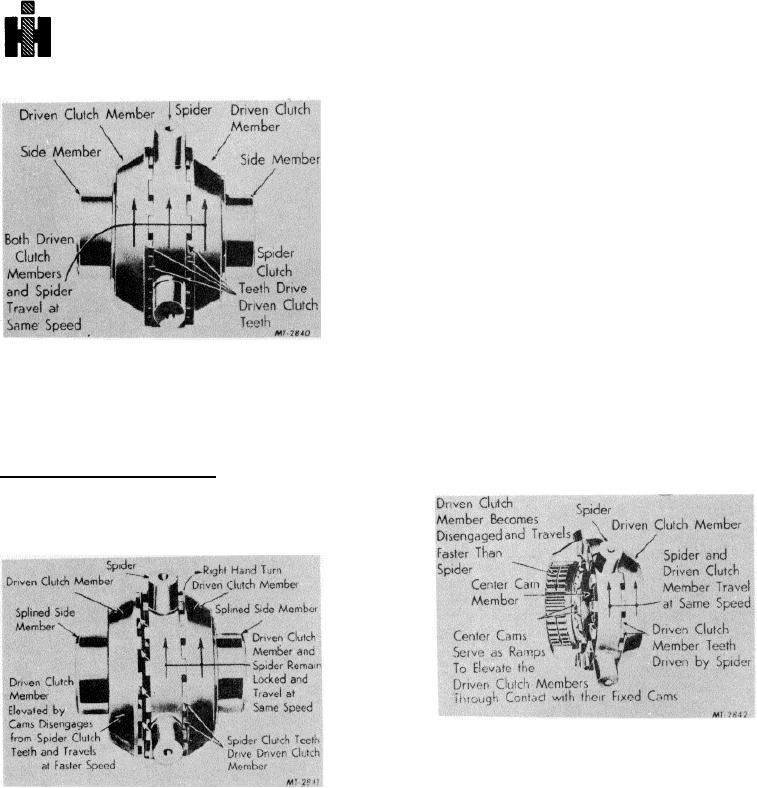

the spider clutch teeth and the corresponding cams (see Fig.

5).

The driving clutch teeth of the spider transmit the driving force

to the driven clutchmember, which in turn drives the right hand

(inside) wheel constantly at ring gear speed, thus propelling

the vehicle. The left hand (outside) wheel covers a greater arc

than the right hand (inside) wheel and driven by the traction of

the road, must turn faster than ring gear speed. Likewise, the

left hand driven clutch member must turn faster than the

spider. In other words, it permits differences in wheel speeds

or differential action. Fig.

6 illustrates how this is

accomplished.

The right hand row of cams on the center cam member are

meshed securely with the cams on the right hand driven clutch

member. With the center cam thus locked in this position so

that it cannot rotate with respect to the spider, its came on the

Fig. 4 Straight Forward Driving

left hand side serve as ramps upon which the mating cams on

the left hand driven clutch member can rise enabling that

shifts the driving force to the opposite set of driving faces on

driven clutch member to disengage from the spider. The

the mating clutch teeth. Again we have the assembly

ramps on the center cam are high enough to permit the clutch

operating as a unit with each wheel being forced to rotate at

teeth on the driven clutch member to clear the teeth on the

ring gear speed.

spider and when the crest of the ramp is passed, the teeth of

the driven clutch member are forced back by spring pressure

Right Hand Turn--Forward Direction

into full engagement with the clutch teeth of the spider.

When making a turn, differential action is required in order to

permit the outside wheel to travel a greater distance, and

faster, than the inside wheel.

Fig. 6 Forward Right Hand Turn

(Cross Sectional View)

This engagement and disengagement or indexing operation

continues throughout the turn with a rapidity that is in direct

Fig. 5 Right Hand Turn--Forward Direction

relation to the speed of the overrunning wheel.

A conventional bevel gear type differential permits the outside

As the vehicle completes the turn and is again driven in a

wheel to turn faster than ring gear speed while the inside

straight forward direction, differential action no longer being

wheel turns slower than ring gear speed. The NoSPIN

required, both driven clutch members become fully engaged

differential allows either wheel to turn faster than the ring gear

with the clutch teeth of the spider, then the operation, as

speed but does not permit either wheel to turn slower than the

described in "Straight Forward Driving" is resumed

ring gear speed when power is applied.

.

When negotiating a right hand turn in a forward direction, the

right hand driven clutch member remains fully engaged with

51