MOTOR TRUCK SERVICE MANUAL

AXLE-REAR

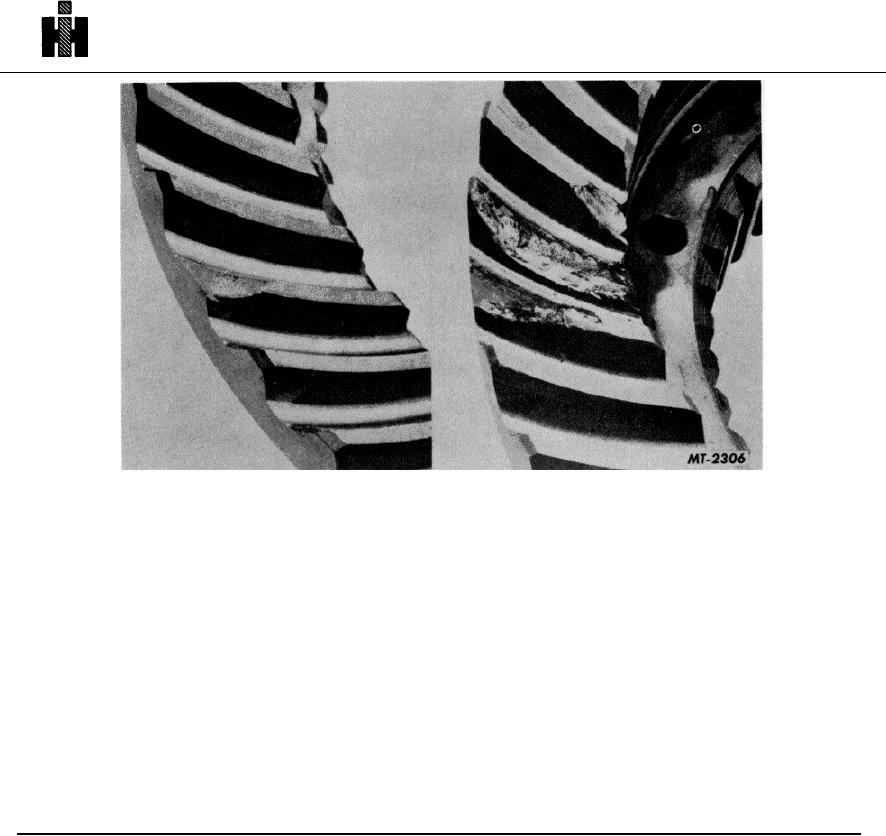

Fig . 3-Fractured Gear Teeth

Fig. 3 illustrates typical examples of fracture to bevel

then adjusted to satisfy two conditions--best possible

gear teeth due to improper gear adjustment. The photo

contact area position and quiet operation. Readjustment

at the left shows a failure that resulted from concentrated

of gears that are believed to be noisy after a period of

contact area at the heel section of the bevel gear caused

service, in general, will aggravate the condition rather

by excessive backlash between the bevel gear and

than eliminate it. Improper adjustment concentrates the

pinion. The illustration at the right shows a fractured

contact area on a small portion of the teeth resulting in

bevel gear in which backlash between the bevel gear

failures of the type shown above.

and pinion was not sufficient, thus producing excessive

loading on the toe section of the gear.

Failures of this type can be avoided by correctly adjusting

the drive gears, when necessary, according to the

Bevel gears are carefully matched with the driving pinion

specifications outlined in the rear axle section of the

before assembly into differential carrier. The gears are

CTS-2001 series service manual.

60