MOTOR TRUCK SERVICE MANUAL

AXLE-REAR

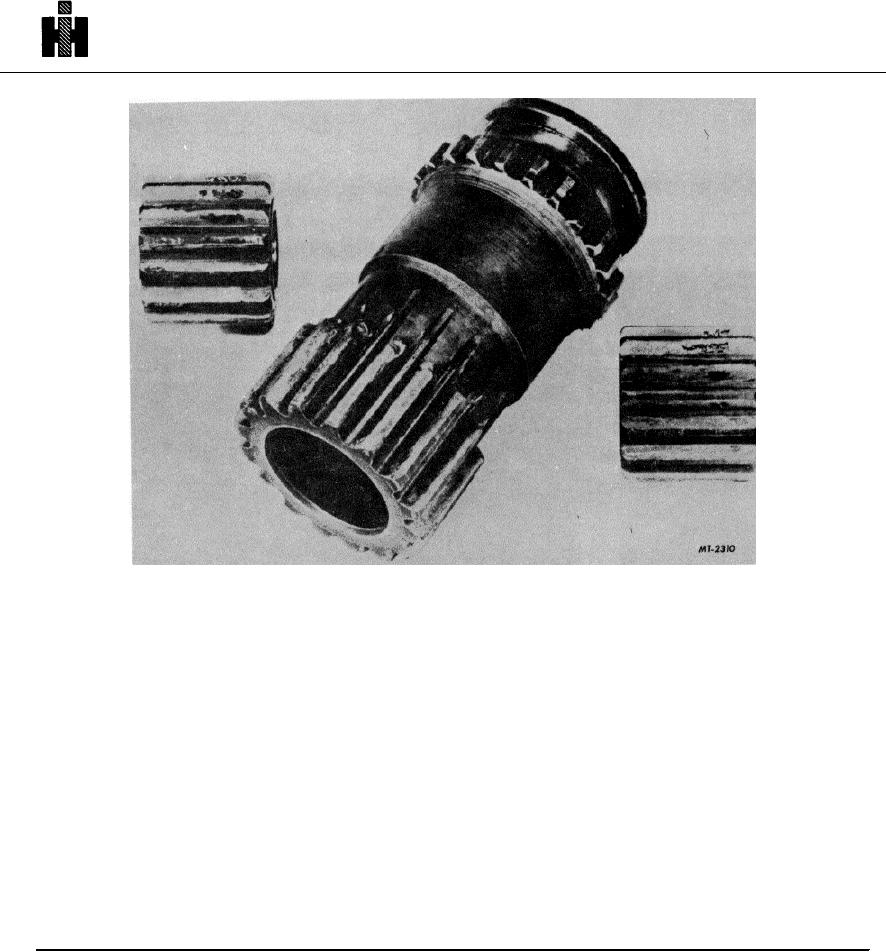

Fig . 7-Pitted Planetary Gear Teeth .

Here are idler pinions and a sliding clutch gea2 damaged

proved they had been correctly heat treated to sufficient

by abnormal pressures. Observe the pitted areas on the

hardness and strength to withstand all normal pressures.

idler pinion teeth near one end and the corresponding

It is therefore evident, normal pressures were greatly

mutilated areas on the gear. Excessive loading created

exceeded in operation and the failure may be readily

deflection in the assembly and the contact areas or

traced to abusive service. Very frequently when damage

bearing areas were concentrated at one end of the teeth.

of this kind occurs, other parts of the unit will be worn to

Consequently, pressures were sufficiently high to break

a point requiring replacement. Thorough examination

through the protecting oil film, permit metal-to-metal

and a complete tear down is the only way a lasting,

contact, and break down the tooth surfaces. Close

satisfactory repair job may be assured. Look for bearing

inspection of Fig. 7 will reveal some of the teeth have

wear, damaged bevel gears, mutilated differential gears

larger pitted areas than others. Merely because some of

and scored idler pinion pins.

these teeth happened to be in contact more frequently at

the instant of clutch ing and pressure application, they

Failures of this type may be easily avoided by loading

were most affected.

within the capacity of the vehicle in consideration of the

working conditions, and putting the trucks under the

Examination of all these gears definitely

control of only capable drivers.

64