AXLE-REAR

MOTOR TRUCK SERVICE MANUAL

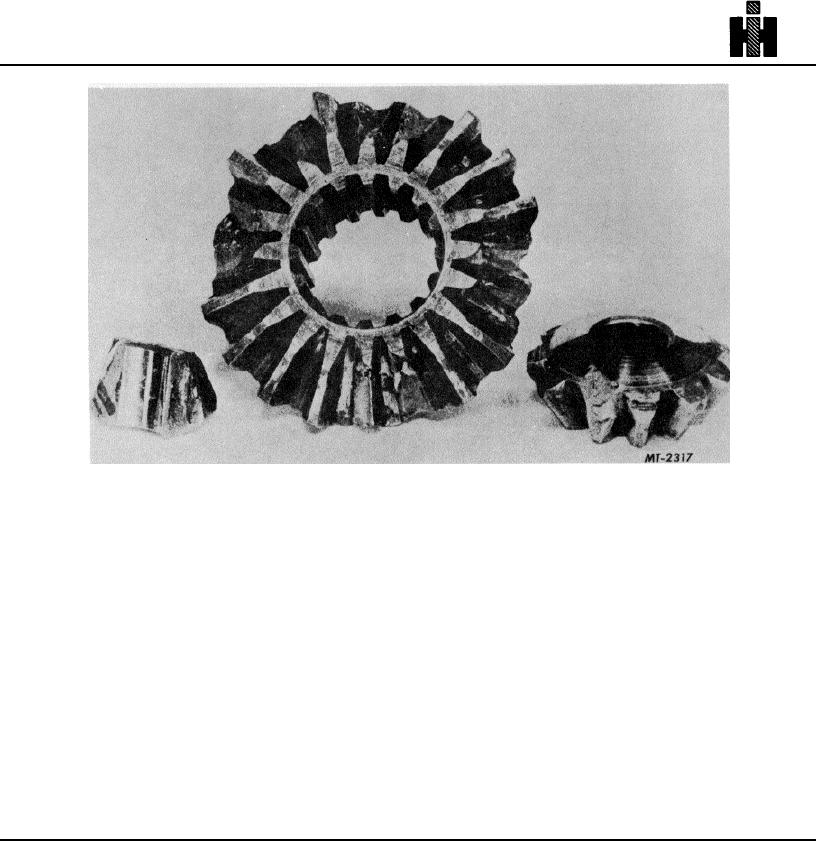

Fig. 14-Shock Fracture

Excessive clutching--commonly known as "bucking" or

axle shafts or cracked bevel gear teeth. If the truck

"frogging"--will very frequently cause differential side

continued in operation after the differential broke up,

gears and side pinions to fail in the manner shown in Fig.

damaged cases, battered idlers, and ruined bearings

14. The fractures are of the shock type--produced by

would most likely be found.

stresses greater than the maximum strength of the parts.

The break occurs at once when the. high abnormal

During the winter months when trucks are operating on

pressures are applied. For this reason, the failure is

icy pavements, trouble of this nature is not unusual.

known as a shock fracture.

Wheels spinning under load and suddenly breaking

through ice to stop against high traction pavement,

In the above illustration, the grainy structure

subject differential gears to fracture creating shocks.

characteristic of all shock fractures is clear. Note how

Severe operations such as construction work and

teeth from the side gear were broken out about 900 apart

logging are apt to develop numerous failures of this kind

where each of the side pinions meshed. One of the side

when ground or working conditions are poor. Lightened

pinions shown received sufficient shock load to cause it

loads are often all that is necessary to eliminate them

to split.

entirely.

With failures of this kind, it is not at all unusual to find

that secondary failures also occurred, such as broken

71