AXLE-REAR

MOTOR TRUCK SERVICE MANUAL

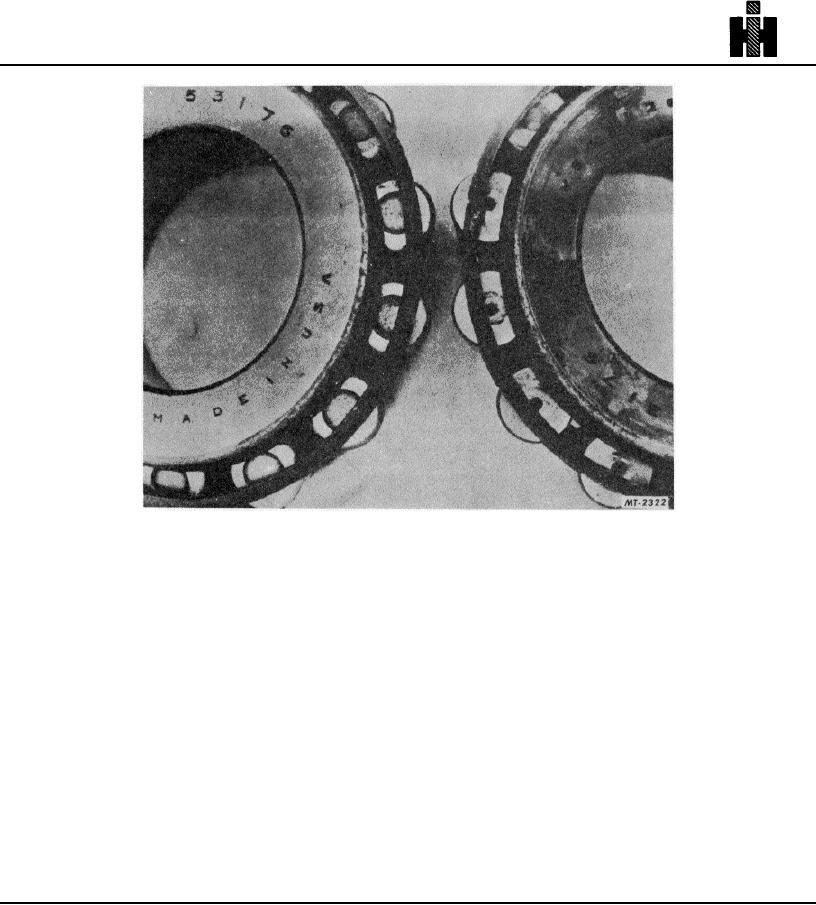

Fig. 19-Roller Bearing End Wear.

The taper bearing shown on the left in Fig. 19 is a new

caused by foreign substance in the lubricant.

bearing. Close examination will reveal the raised ground

As a result of this wear, the pinion was no longer held in

and polished shoulder on the roll ends that contact a

proper position relative to the ring gear. The gears were

matching shoulder on the inner race. The dark center

"out of adjustment. " Continued operation, with end play

area is considerably lower than the roll end shoulder.

in the pinion damaged the contact area of the bevel teeth

which created noise.

The bearing shown in on the right in Fig. 19 has been

removed from a unit after a period of service. The bevel

The use of recommended lubricants changed at

gears were noisy and required replacement. Comparing

reasonably regular intervals will prevent the majority of

the roll ends of this bearing with those of the new one,

such failures.

the difference is immediately apparent.

Here the

shoulder has worn completely away and below the

Readjustment of bearings damaged in this manner will

original height of the center recessed area.

not give a satisfactory repair job, as they will continue to

wear rapidly--they should be replaced.

The

lapping

and

wear

of

the

roll

ends

were

New bearing assemblies should always be installed

along with new gear sets.

76