TRUCK SERVICE MANUAL

BREAK-AIR

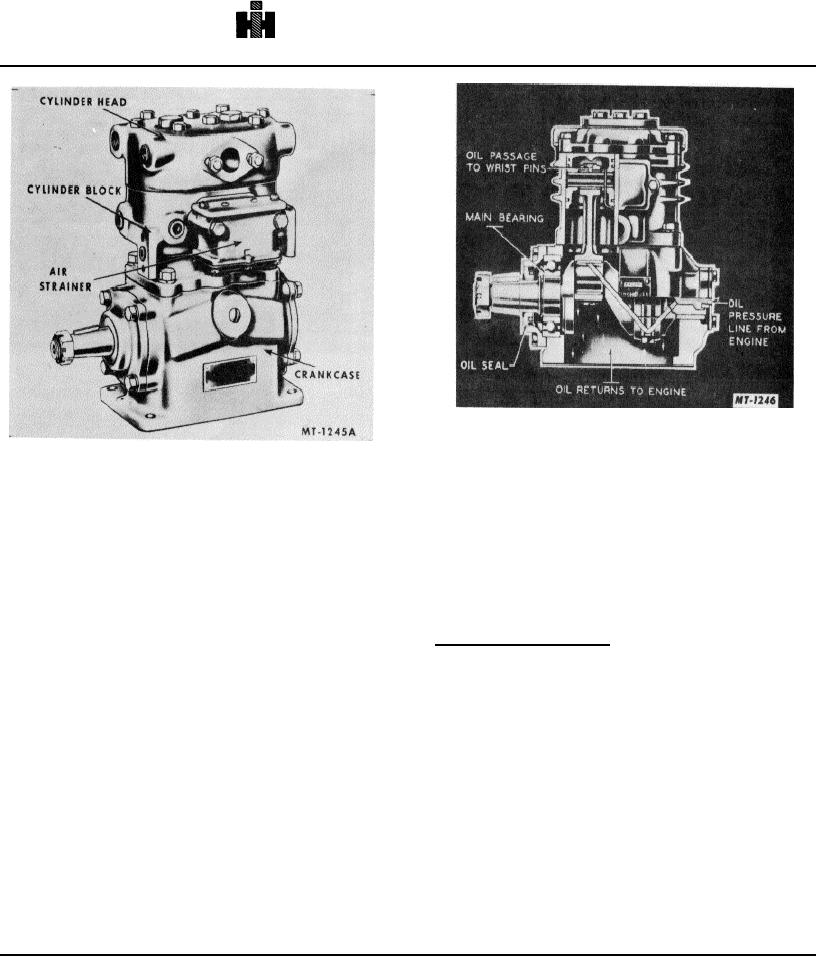

Fig .

2 Sectional View of Compressor Oiling System

Fig .

1 Exterior View of TuFlo 400 and 5 Compressor

OPERATION

DESCRIPTION

The compressors run continuously while the

engine is running, but the actual compression of air is

The TuFlo

500

compressors are single

controlled by the governor, which, acting in conjunction

acting reciprocating piston type compressors. The rated

with the unloading mechanism in the compressor

capacity of a compressor is based on the piston

cylinder block, starts or stops the compression of air by

displacement in cubic feet per minute when operating at

loading or unloading the compressor when the pressure

1250 RPM.

in the air brake system reaches the 'desired minimum

(8085 p. s. i. ) or maximum (100105 p.s. i. ).

The capacity of the TuFlo

500 is 12 cubic feet per minute.

Compressing Air (Loaded)

The TuFlo 500 and 600 compressors

During the down stroke of each piston a partial

have water-cooled cylinder heads and water-cooled

vacuum is created above the piston which unseals the

cylinder blocks. Various mounting and drive adaptations

inlet valve, allowing air drawn through the intake strainer

are used depending on design of the engine.

to enter the cylinder above the piston, Fig. 3. As the

piston starts the upward stroke, the air pressure on top of

Engine lubricated compressors are dependent

the inlet valves plus the inlet valve return spring force

on the vehicle engine for oil and oil pressure, Fig. Z. In

closes the inlet valve. The air above the piston is further

these compressors oil from the vehicle engine enters the

compressed until the pressure lifts the discharge valve

compressor through a passage in the compressor end

and the compressed air is discharged through the

cover and is fed to the connecting rod bearings through

discharge line into the reservoir, Fig. 4. As each piston

drilled holes in the crankshaft. The wrist pins are

starts its down stroke the discharge valve above it

lubricated through holes in the top of the connecting rod

returns to its seat, preventing the compressed air from

wrist pin bearing and bushing by means of oil dripping

returning to the cylinder, and the same cycle is repeated.

from a drip boss on the piston. The main bearings are

splash lubricated. Surplus oil returns to the engine

crankcase through the open compressor base.

127