BREAKS-AIR

TRUCK SERVICE MANUAL

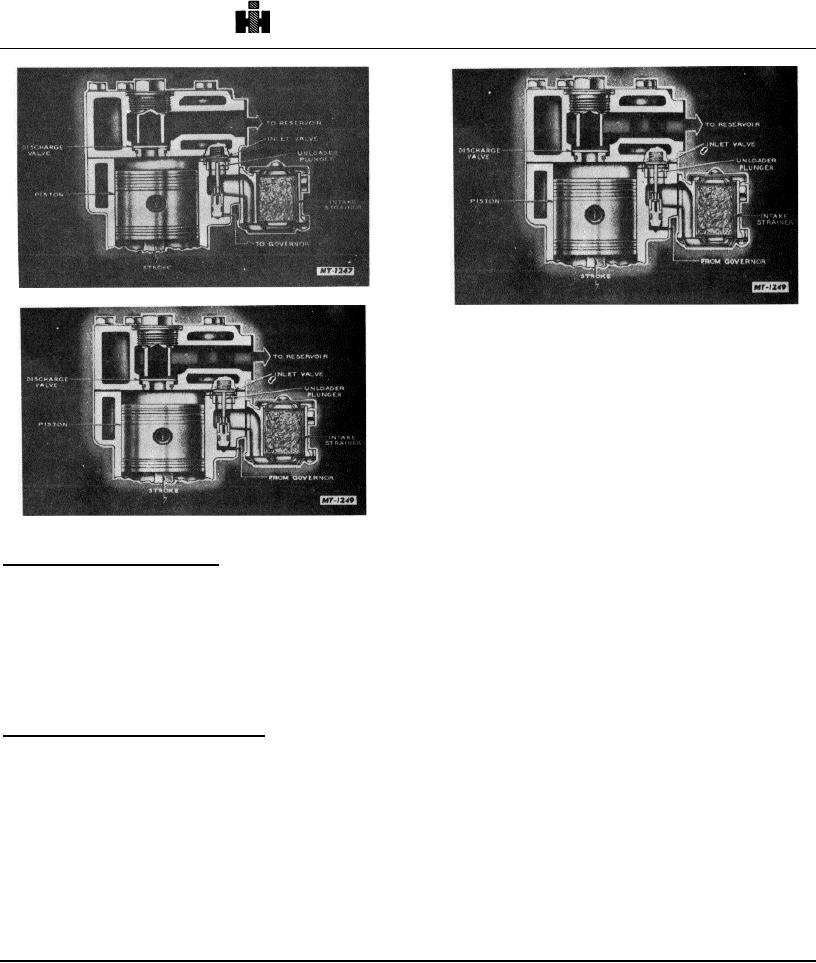

Fig. 3 Intake of Air

Fig. 5 Compressor Unloading Mechanism

REMOVE

1. Drain air brake system.

2. Drain engine cooling system, compressor

cylinder head and compressor cylinder block.

3. Disconnect all air, water and oil lines connected

to compressor.

4. Remove compressor drive belt.

5. Remove compressor mounting bolts and remove

compressor from engine.

6. Use a suitable puller to remove the pulley from

Fig. 4 Compression of Air

the compressor crankshaft after removing the

crankshaft nut.

Not Compressing Air (Unlogded)

DISASSEMB LY

When the air pressure in the reservoir reaches the

maximum setting of the governor (100105 p. s. i. ),

Remove grease or dirt from the exterior of the

compressed air from the reservoir passes through the

compressor by scraping, if necessary, followed by the

governor into the cavity below the unloading pistons in

use of cleaning solvent and a brush.

the compressor cylinder block. This air pressure lifts the

unloading pistons, which, in turn, lift the inlet valves off

TuFlo compressors should have the following

their seats, Fig. 5.

items marked showing proper relationships prior to

disassembly. Center punch marks can be used if

Passage of Air During Noncompression

desired.

With the inlet valves held off their seats the air

during each upstroke of the piston is forced through the

1. Position of cylinder block in relation to

air inlet cavity and to the other cylinder where the piston

is on the down stroke.

2. Position of end covers in relation to the

When the air pressure in the reservoir is reduced to the

minimum setting of the governor (8085 p. s. i. ), the

3. Position of crankshaft in relation to crankcase.

governor releases the air pressure beneath the

unloading pistons. The unloading piston return spring

then forces the pistons down and the inlet valve springs

return the inlet valves to their seats and compression is

resumed.

128