BREAKS-AIR

TRUCK SERVICE MANUAL

position when the two locking slots in the bearing inserts

and in the rod and cap are both located adjacent to the

same connecting rod bolt. Then install the lock wire

through both capscrew heads and secure. Install the two

capscrews and slotted nuts. Then install cotter pins in

the capscrews.

Turn crankshaft until other journal is downward

and install second connecting rod and piston in same

Fig. 10 Installing Wrist Pin Lock Wire

manner.

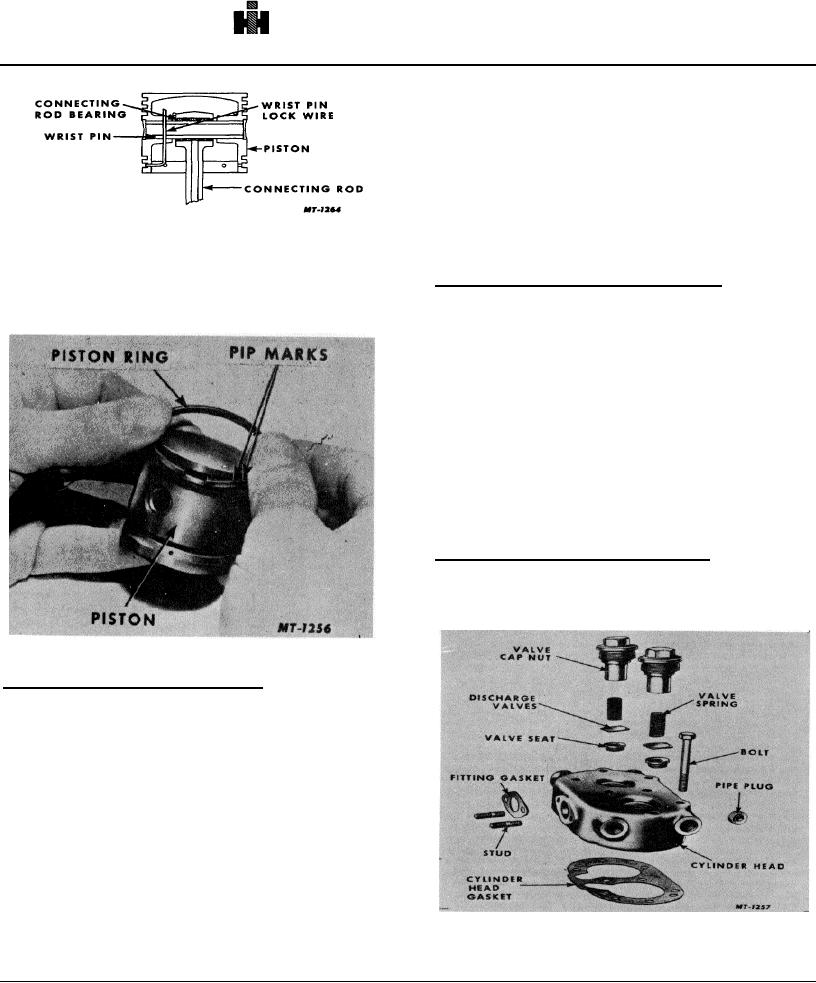

Install piston rings by hand, Fig. 11. Particular

Assembling and Installing Unloader Pistons

care must be taken when installing piston rings so that

the pip mark on the ring is toward the top of the piston.

Lubricate the unloader piston bores in the cylinder

Stagger the position of the ring gaps.

block and also the unloader piston and unloader piston

grommet with clean engine oil. If new unloader kits are

being installed, the pistons in the kit are prelubricated.

Install unloader piston grommet on unloader piston.

Install unloader pistons and unloader plungers through

the top of the cylinder block taking care to avoid cutting

the unloader piston grommets on the block. Install

unloader spring saddle on unloader plungers. Install

spring seat in top of cylinder block strainer opening and

place unloader spring between spring guide and spring

saddle. Install inlet valve guides if they have been

previously removed.

Assembling and Installing Cylinder Heads

Install discharge valve in the cylinder head.

Install discharge valve spring and discharge valve cap

nut, Fig. 12.

Fig. 11 Installing Piston Rings

Installing Pistons and Connecting Rods

Before installing pistons and connecting rods,

thoroughly lubricate pistons, piston rings, wrist pin

bearings and connecting rod bearings with clean engine

oil.

Turn crankshaft so as to position one crankshaft

journal downward. Remove bearing cap from connecting

rod.

Insert the connecting rod and piston through top of

number one cylinder so that the connecting rod bearing

makes contact with the crankshaft journal. Position and

Fig, 12 Exploded View of Cylinder Head

attach bearing cap to rod. The cap is in the correct

133