TRUCK SERVICE MANUAL

ELECTRICAL

NOTE: Before starting to disassemble the starting motor

motor terminal and lead from solenoid ground

etch mark the field frame, lever housing and the nose

terminal.

housing so they may be reassembled in the same

2. Motors which have brush inspection plates,

position.

remove the plates, then remove the brush lead

screws which disconnect the field leads from the

brush holders.

3. Separate the commentator end frame from the

field frame.

4. Separate the nose housing and field frame from

the lever housing.

5. Remove the armature and clutch assembly from

lever housing.

6. Separate solenoid from lever housing by pulling

apart.

INSPECTION AND REPAIR

1. Brushes and Brush Holders-- Inspect the

brushes for wear. If they are worn down to one-

half their original length, when compared with a

new brush, they should be replaced. Clean

brush holders and be sure that the brushes will

not bind in the holders. The full length of the

brush surface should ride on the commentator

with spring tension to provide a good contact.

Inspect the brush leads and screws to be sure

they are tight and clean.

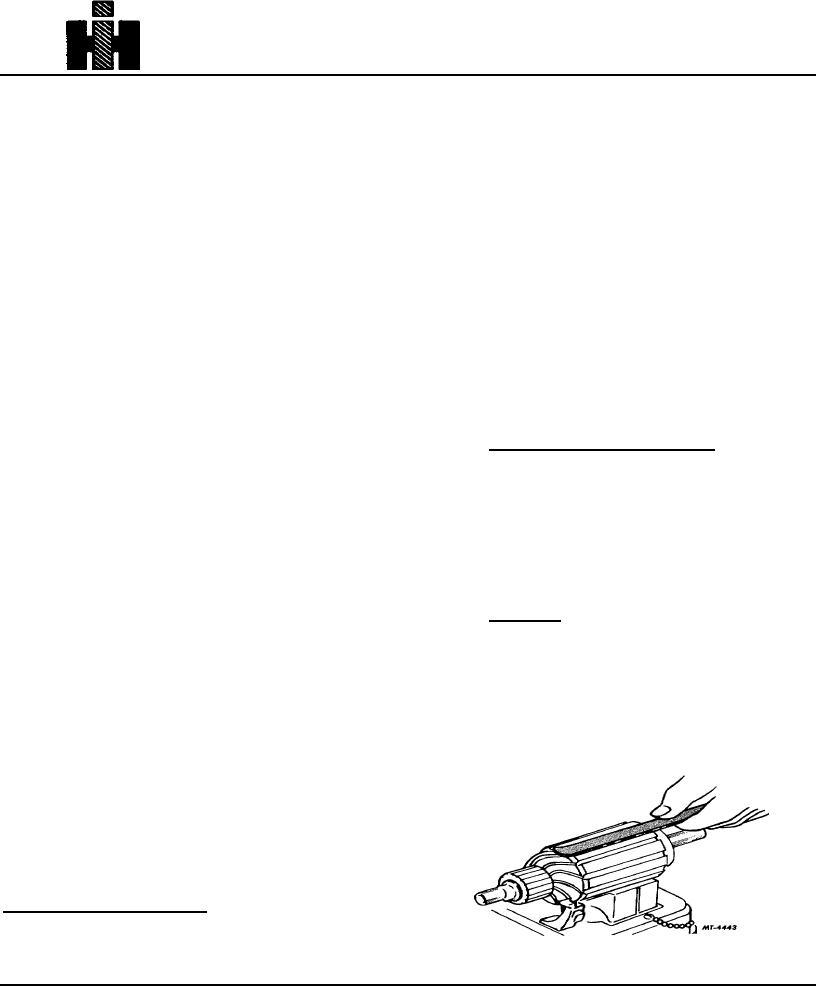

2. Armature-- Inspect the armature to be sure there

are no short circuits, open or grounds.

a. Short circuits are located by turning the

armature in a growler while holding a steel

strip on the armature. The steel strip will

vibrate on the area of the short circuit, see

Fig. 11.

Heavy Duty Drive Clutch Motor

1. Disconnect field coil connector from solenoid

Fig. 11 Testing Armature for Short Circuits

285