TRUCK SERVICE MANUAL

ELECTRICAL

CLUTCH ASSEMBLIES

b. Opens are usually found where the conductors

Four kinds of clutches or motor drives (a heavy

are joined to the commutator. Loose or poor

duty sprag, a Positork drive, an intermediate duty type

connections will cause arcing and burning of the

and a splined drive) may be used on the enclosed shift

commutator. If the bars are not burned too bad,

lever heavy duty motors.

resolder the leads in the riser bars and turn the

commutator down in a lathe. Then under cut the

The intermediate clutch may be either the sprag

insulation between the commutator bars 1/32".

type or the four roll type. All four types are moved into

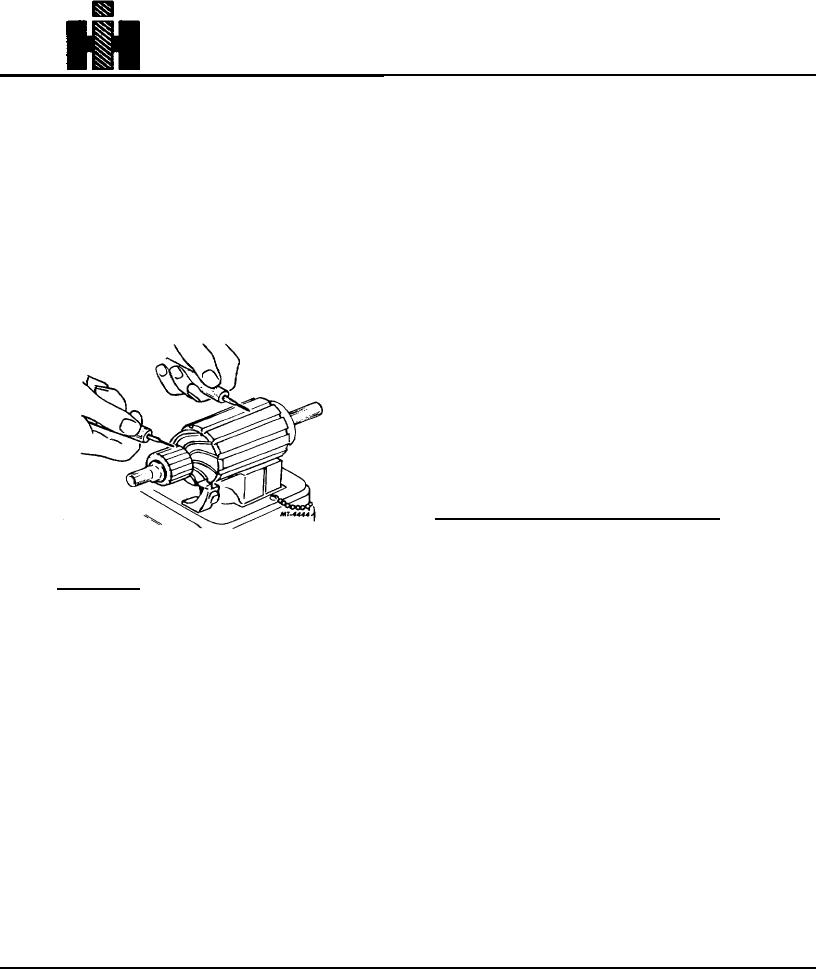

c. Grounds in the armature can be found using a

mesh with the flywheel ring gear by action of the

test lamp and prods, see Fig. 12 If the lamp

solenoid. The pinion will remain engaged until starting is

lights when one prod is positioned on the

assured and the solenoid is interrupted.

commutator and the other prod on the armature

core or shaft the armature is grounded.

If the commutator is worn, dirty or out-of-round

or the insulation is high, the commutator should

be turned down and under cut.

4. Reassembly is the reverse of the disassembly.

Heavy Duty Sprag Clutch and DR250 Drive

1. Remove the cupped pinion stop and split

washer. When removing the cupped pinion stop

Fig. 12 Testing Armature for Grounds

it will probably be damaged. A new one will be

required at time of reassembly.

3. Field Coils-- Check field coils for grounds and

opens with a test lamp.

2. Remove remaining parts such as pinion washer

or retainer cups and baffle if equipped. The

a. Grounds With the field coil ground

splined drive will have a spring cup (spring inside

disconnected, position one test prod on

cup).

the field frame and the other to the field

connector. If the lamp lights the field coils

3. DO NOT lubricate the sprags on heavy duty

are grounded and must either be replaced

clutches as they are lubricated for life with a

or repaired.

special lubricant.

b. Opens If the test lamp does not light when

4. Reassembly is the reverse of the disassembly.

the prods are connected to the ends of coil

leads, the field coils are open.

REASSEMB LY

The reassembly procedure for the most part is the

A pole shoe spreader and pole shoe screw driver

reverse of the disassembly.

should be used if the field coils are to be removed. Extra

caution should be taken in replacing the field coils to

prevent grounding or shorting when they are tightened in

place. If the pole shoe has a long lip on one side, it

should be assembled in the direction of armature

rotation.

286