TRUCK SERVICE MANUAL

FUEL SYSTEM

21. If plunger sticks because of misalignment,

loosen cup retainer, rotate cup one fourth turn,

and retorque. Repeat as necessary.

22. Remove plunger from adapter and lubricate

plunger with test oil. Install spring on plunger

and insert into adapter.

23. Check plunger leakage on ST990 or ST570 as

described c the following pages.

24. Check cup spray pattern on ST668 as described

on the following pages.

25. Another method of checking open cup spray

holes is follows:

a. Remove plunger and spring.

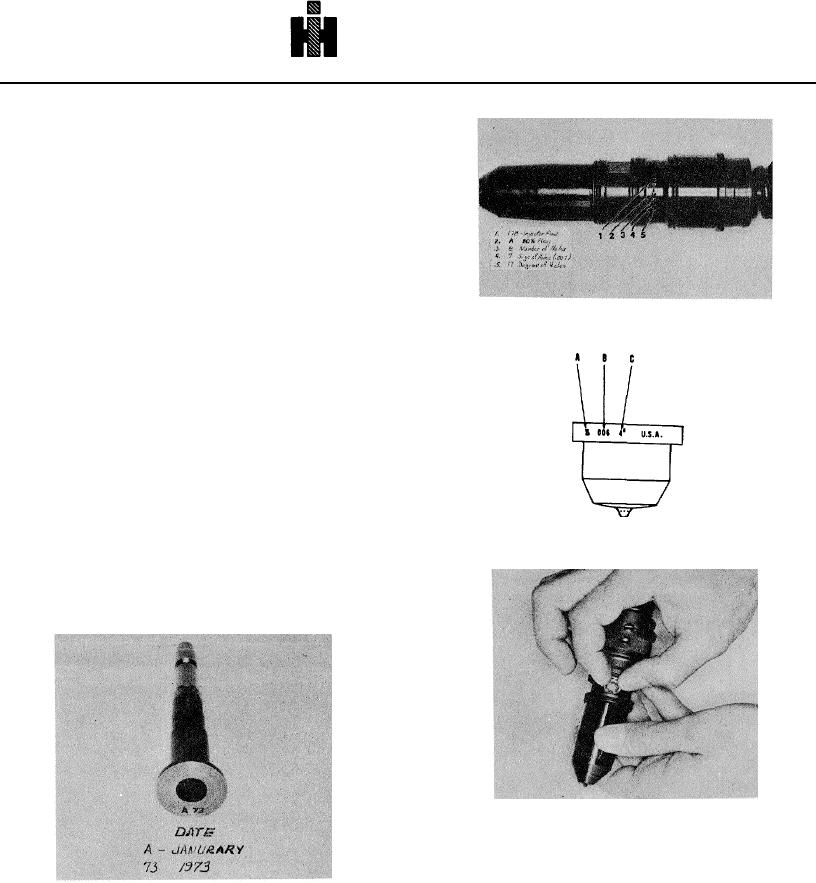

Fig. 6-1-40, F60200. Size location on Injector adapter

b. Fill barrel and cup full of fuel oil.

c. Insert plunger with ST1089, less spring, into

inject( forcing fuel out spray holes. Fig. 6138.

Caution: At anytime fuel is forced

from cup spray holes be sure to keep

hands or body out of pray stream to

prevent injury.

d.

Remove plunger and install spring.

26.

Lubricate and install new "Viton" "O" rings into

proper grooves in adapter.

Note: Viton "O" rings are identified by a

A HOLES

B SIZE

C ANGLE

green band.

Fig. 6-1-41, F60201. Size marking on Injector cup

27.

Install new fuel inlet screen and retainer. Fig.

6142.

28.

After assembly, store in clean place until ready

for leakage test.

Fig. 6-1-42, F60202. Fuel inlet screen and retainer

Fig. 6-1-39, F60199. Marking location on plunger

464