TRUCK SERVICE MANUAL

Table 6-1-4: Injector Spring Data

Approximate

Wire

Load Required to Compress Springs to Length

Part

Free Length

No.

Dia.

Length

New Min.

New Max.

Worn Limit

No.

Inches [mm]

Coils

Inches [mm]

Inch [mm]

Lb. [kg]

Lb. [kg]

Lb. [kg]

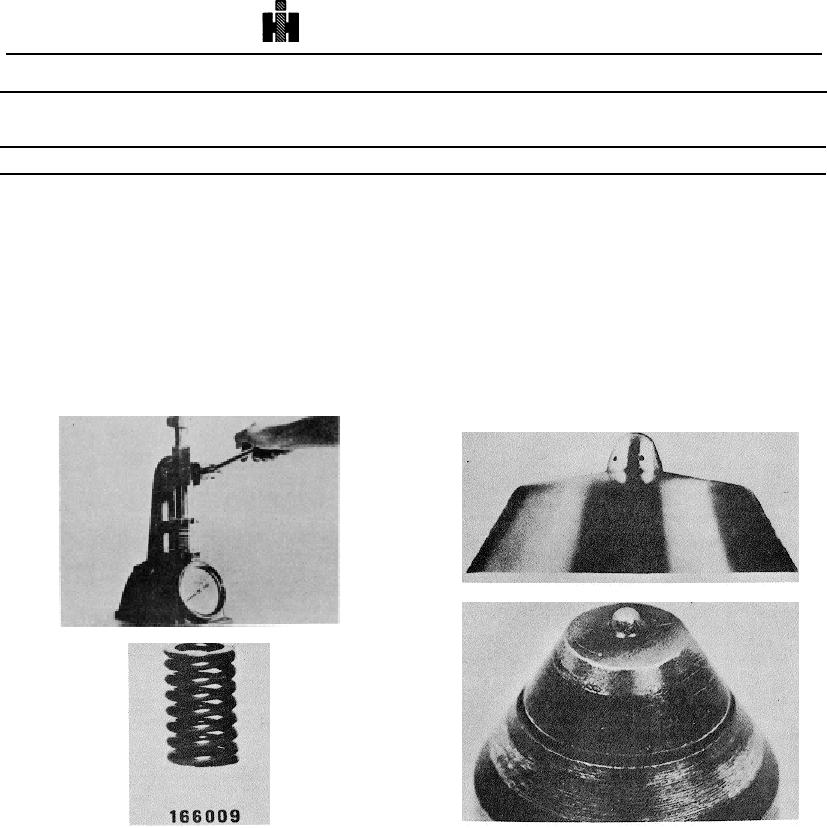

166009

1.95 [49.7]

8

0.187 [4.75]

1.663 [42.2]

143,25 [65]

158.75 [72]

138 [63]

6. Check socket for wear or cracking

Injector Cup

Caution: Handle injector plunger with care to

1. Inspect injector spray holes and tip with magnifying

glass. Compare with new cup shown in Fig, 6-1-17.

prevent damage which could render it useless.

Discard cup if any of following conditions exist.

a. Abrasive wear. This wear can begin internally,

Injector Spring

therefore, inspect both interior and exterior. Fig. 6-

1-18.

1. Check spring for excessive wear or mutilation.

b. Corrosion damage and effect of excessive heat:

This condition usually results from high acid or

2. Test spring tension on spring tester, Fig. 6-1-15,

sulphur content in fuel or overload operating

that is capable of very accurate measurements of

conditions. Fig. 6-1-19.

spring lengths and applied load by means of

c. Enlarged or distorted spray holes. Caused by

standards and dial indicator gauge. Table 6-1-4

cleaning with drills or other instruments.

Fig. 6-1-17, F60105. New injector cup tip

Fig. 6-1-15, F60163. Testing injector spring

Fig. 6-1-18, F60223. Cup tip damaged by wire brushing

Fig. 6-1-16, Injector spring

2. Inspect cup for plunger seat pattern. If plunger seat

3. If injector springs compress to dimensions shown, at

covers 40 percent continuous area around cup cone

less than load indicated under "worn limits," springs

or plunger bore, it is possible cup may be reused, but

must be discarded.

it must pass the ST-990 cup-to-plunger leak test.

Seat location is not important. Fig. 6-1-20.

Caution: Never alter size of injector cup spray

holes.

460