TRUCK SERVICE MANUAL

Compressed Air:

Direct a jet of dry, clean air against inside or clean air

side of the filter element. Holding nozzle about six

inches away from element, move nozzle up and down,

rotating element until no dust is visually being removed

(approxi-mately 10 minutes). Direct air perpendicularly

to pleats using 100 psi maximum air pres-sure. Do not

damage element with the air flow from nozzle.

Washing:

Filter element can be cleaned by washing in water

using a nonsudsing detergent. Proportions are 2 oz. of

cleaner to 1 gallon of water. For best mixing results use

a small amount of cool tap water, then add to warm (70

- 140F) water to give proper proportions. The warmer

(100F) the solution, the better the cleaning. Soak

element for 15 minutes, then rotate element back and

forth with clean water. If a hose is used to wash or rinse

the filter, be careful not to rupture the paper with the

water jet. Rinse the filter element until drain water be-

comes clear. Proper rinsing is very important. Let filter

element air dry completely before using. Do not use

compressed air for drying.

IMPORTANT: After cleaning filter element using either of

the above recommended methods, inspect the filter

element for damage:

1. Dust on downstream (inside) or clean air

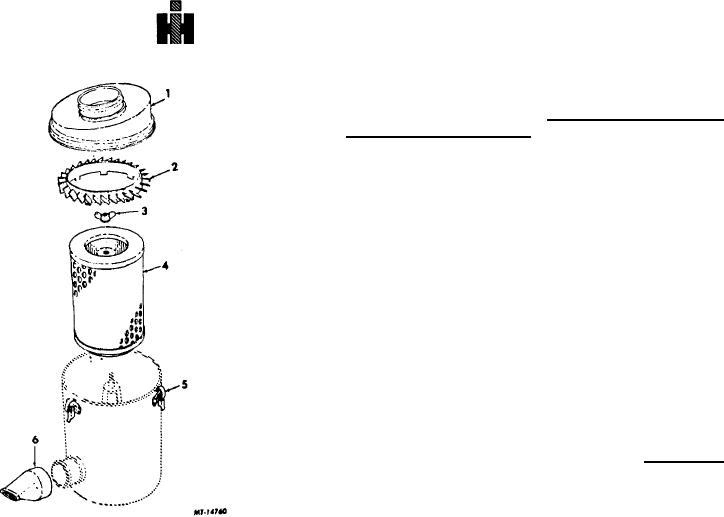

Fig. 2 Heavy Duty Dry Type Air

side,

Cleaner

2. Slightest ruptures.

3. Damaged gaskets.

Legend for Fig. 2.

Ruptures can be detected on any dry type element

1

COVER, Air Cleaner

by placing a light inside the filter element. Inspection of

2

RING, Fin

the element on the outside will then disclose any holes or

3

NUT, W/Gasket, Wing

ruptures. Any hole in the filter element, even the

4

ELEMENT, Air Cleaner

smallest, will pass dust to the engine and cause engine

5

CLAMP, Cover (3 Required)

wear.

6

VALVE, Evacuator

456