TRUCK SERVICE MANUAL

AIR CLEANER

GENERAL

These air cleaners are equipped with an evacuator

valve as shown in Fig. 2, item 6.

Air must be clean if engine is to de-liver proper

performance throughout its life span. Dirty air introduced

The vacuator valve should be inspected at regular

into the engine may ruin the carefully engineered close

intervals to be sure the valve is not plugged due to the

tolerance of the engine.

presence of lint, chaff, etc. which may collect in the

Air cleaners are designed to supply clean air to the

valve. The vacuator valve can easily be removed and

engine; and if not kept clean, the supply of air will

cleaned.

become restricted. This will cause loss of power,

sluggish performance and poor gas mile age.

Do not allow dust level in cup to build up to within "

of slot (cutaway lip on baffle flange) in the cup baffle.

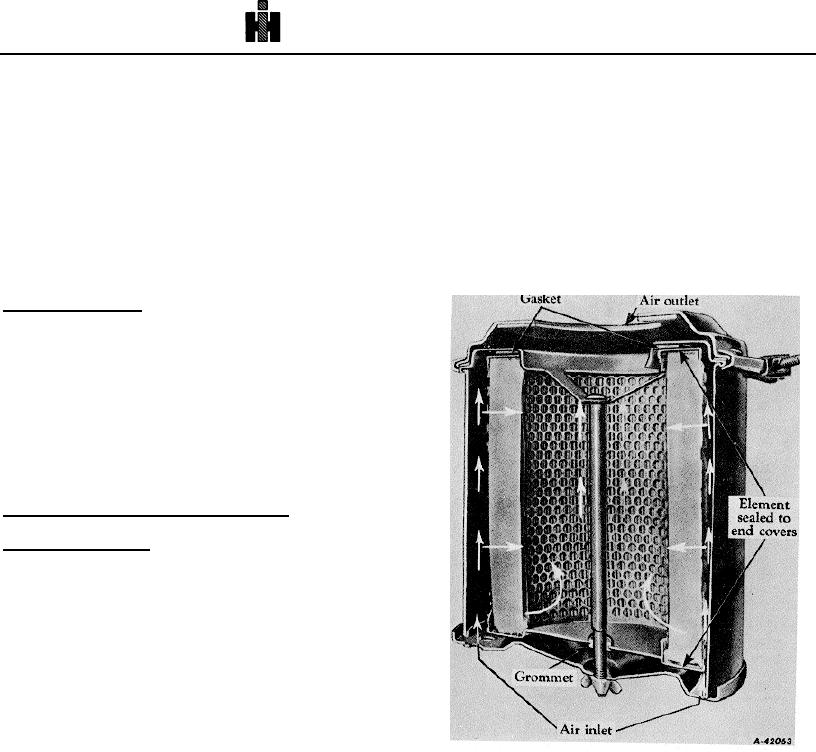

Dry Type Air Cleaner

The dry type air intake filter, Fig. 1) em ploys a dry

type paper element which is sealed at the outlet end so

that all air drawn into the engine must enter through the

element. There is no oil used in this unit, hence, the

reference to "dry type." The direction of air flow in this

filter is from the outside to the inside of element,

permitting excess foreign particles to fall free from the

outside of the element during road operations. This

action prolongs the service period of the filter.

AIR CLEANER SERVICE INSTRUCTIONS

Dry Type Air Cleaners

Heavy-duty: Shown in Figure 2

Loosen clamps and remove dust cap, wipe out dust and

clean gasket. Do not use solvents, gasoline or oil to

clean cup. Daily inspection of the air cleaner dust cup

should be made if dusty conditions warrant. Do not allow

dust deposits to build up past 2" level in cup.

Do not strike the bottom rim of the cartridge against

any hard surface. Damage could result to the rim and

affect the sealing at reassembly.

Fig. 1 Dry Type Air Cleaner

The dry type filter element can be washed with a

nonsudsing household detergent. Use warm water

Excessive smoke or loss of power are good

(120-140F). Flush filter with gentle stream until drain

indications that the filter element should be re-placed or

water is clean. Air dry filter before using. Also inspect

cleaned. Clean or replace every 5, 000 to 25, 000 miles

after every cleaning for damage or rupture. Re-place

or every 150 to 750 hours depending upon dust

filter every 10, 000 to 20, 000 miles depending on dust

conditions.

conditions.

Wipe all internal parts clean before

reassembly. Replace gaskets regularly.

The filter element can be cleaned several times

before replacement is necessary.

Recommended

cleaning methods for the filter element are:

455