TRUCK SERVICE MANUAL

SPRINGS

DESCRIPTION

SERVICING

Constant Rate

Although the exact servicing procedures are different

for each type of spring assembly and spring assembly

Constant rate springs are leaf-type spring

application, the basic procedures are similar. The

assemblies that have a constant rate of deflection. For

following is a general out line for servicing all spring

example, if 500 lbs. deflect the spring assembly 1 inch,

assemblies used on IH vehicles.

then 1000 lbs. would deflect the same spring assembly

Removal

2 inches. Thus, the rate of deflection is constant.

1. Place floor jack under truck frame and raise truck

Constant rate springs are mounted to the axle with

sufficiently to relieve weight from spring to be

U-bolts, nuts and lockwashers. The front end of the

removed.

spring is mounted to a stationary bracket while the rear

end of the spring is mounted to a spring shackle. The

2. Remove shock absorbers where used.

shackle allows for variations in spring length during

compression and rebound of the spring.

This type of spring assembly is used in both front

and rear applications on IH vehicles.

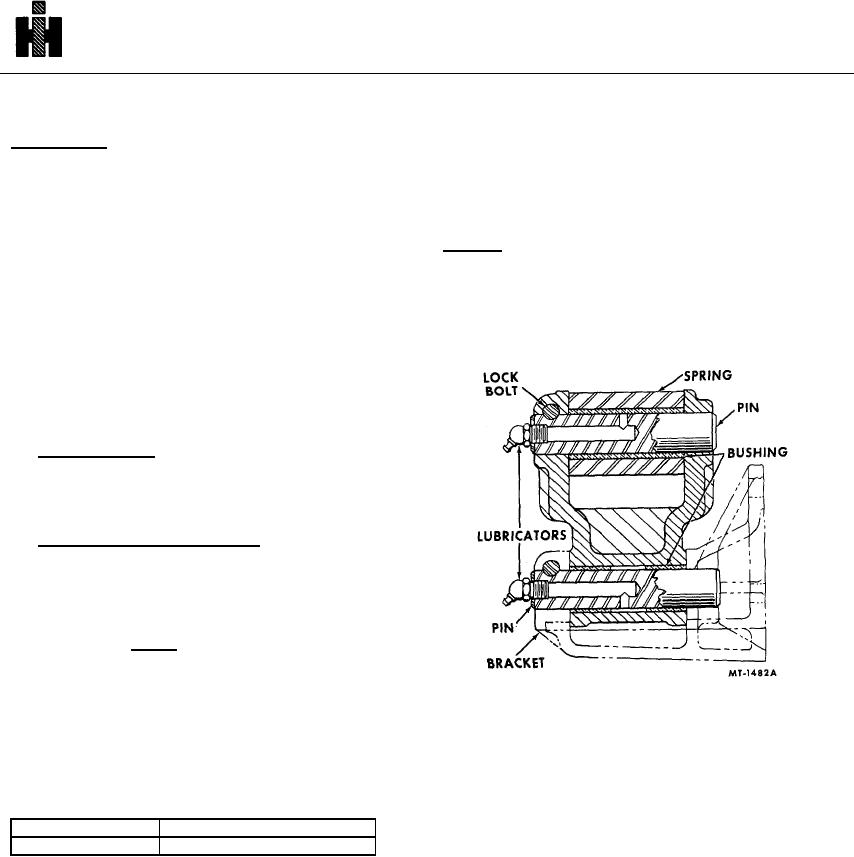

Spring Shackles (Figs. 7 allow for

variations in spring length during compression

and rebound of spring. Shackles pivot on either

lubricated spring bracket pins

Spring Bracket or Shackle Pins used on IHI

trucks will be one of the following three types.

2. Pins that are driven into shackles or

brackets.

Fig. 7 Lubricated Spring Shackle (Driven-in

type spring pin).

TORQUE CHART

FOR ASSEMBLY OF SUSPENSION U-BOLTS

ROLLED THREAD U-BOLTS

7/8"-14

225 - 275

1" -14

325 - 400

NOTE: When servicing suspension assemblies, all U-

bolts must be thoroughly cleaned and lubricated

with Tectyl 400-CWD or equivalent before

reassembly.

608