TRUCK SERVICE MANUAL

PROPELLER SHAFT

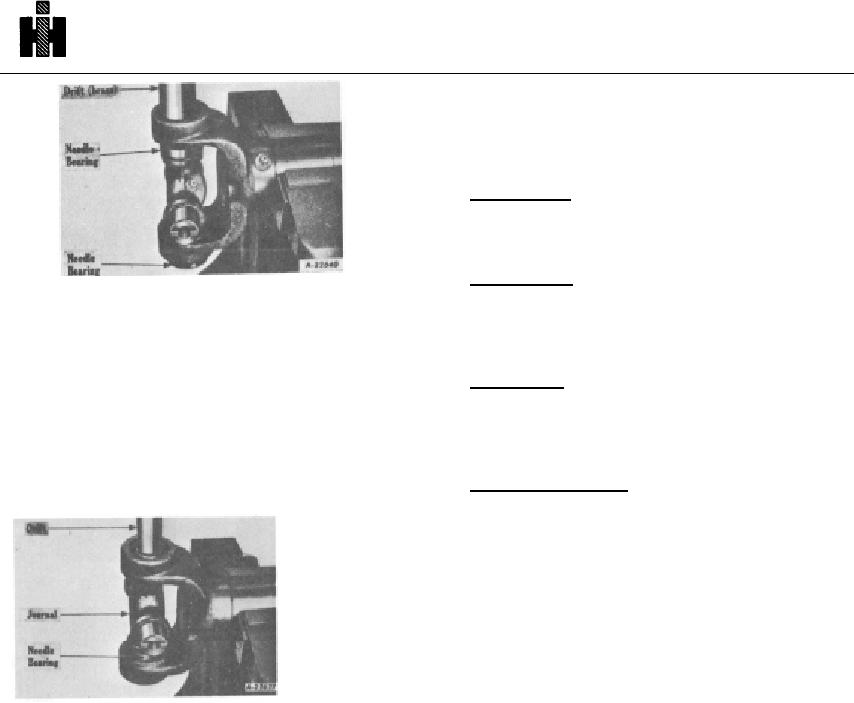

Fig. 20

CLEANING AND INSPECTION

1. Clean All Parts -Use a suitable cleaning fluid. Allow

the parts to remain in the cleaner for some time to

loosen up any particles of grease or foreign matter.

Remove any burrs or rough spots from any

machined surfaces.

2. Needle Bearing -Do not disassemble.

Fig. 18

Clean with a short stiff brush and blow out with

compressed air. Work a small quantity of lubricant

d. Remove the snap ring from the slip joint or yoke.

(See Operators Manual) into each needle bearing

Turn the joint over and remove the opposite snap

and turn the needle bearing on the trunnion to check

ring, Fig. 17.

wear. Replace if worn.

e. Tap the needle bearing until the opposite needle

3. Journal Cross -Because worn needle bearings used

bearing is free of the yoke, using a soft round drift

with a new journal cross or new needle bearings

(brass) with a flat face about 1/32" smaller than the

used with a worn journal cross will wear more rapidly

diameter of the hole in the yoke to prevent damage

(making another replacement necessary in a short

to the bearing, Fig. 18.

time), always replace the journal cross and four

f. Turn the yoke or joint over and tap on the exposed

needle bearings as a unit.

end of the journal or cross end to remove the

4. Journal and Bearing Kit -To facilitate replacement of

remaining needle bearing, Fig. 19.

journals and bearings, a journal and bearing kit is

available. The use of the kit insures having the

correct individual parts when required and saves

valuable time.

REASSEMBLY SOLID CROSS TYPE

Reassembling is merely a reversal of the foregoing

disassembling operations. On joints without a lubrication

fitting, repack the reservoir in the journal cross ends with

a good grade of lubricant (See Operators Manual).

Make sure the reservoirs in each trunnion are filled.

With the rollers in the race, fill the race, fill the race about

Fig. 19

one-third full.

g. Remove the journal cross from the yoke. Tip the

cross as shown in Fig. 20 and lift it out of the yoke.

606