TRUCK SERVICE MANUAL

PROPELLER SHAFT

General

should indicate same number of degrees previously

determined with protractor at engine (90 degrees minus

engine angle).

If engine angle and yoke angle are not the same or

within 1/2 degree of each other, check opposite lug

before taking corrective measures.

If excessive misalignment still exists, replace yoke and

recheck.

If bearing retainer and cap are integral, protractor

may be placed on cap--providing cap is flat. If cap is

dome shaped, remove cap and bearing and place

protractor on outside machined surface of yoke lug, Fig.

20.

Yoke Horizontal Alignment

Procedures for checking horizontal alignment of a

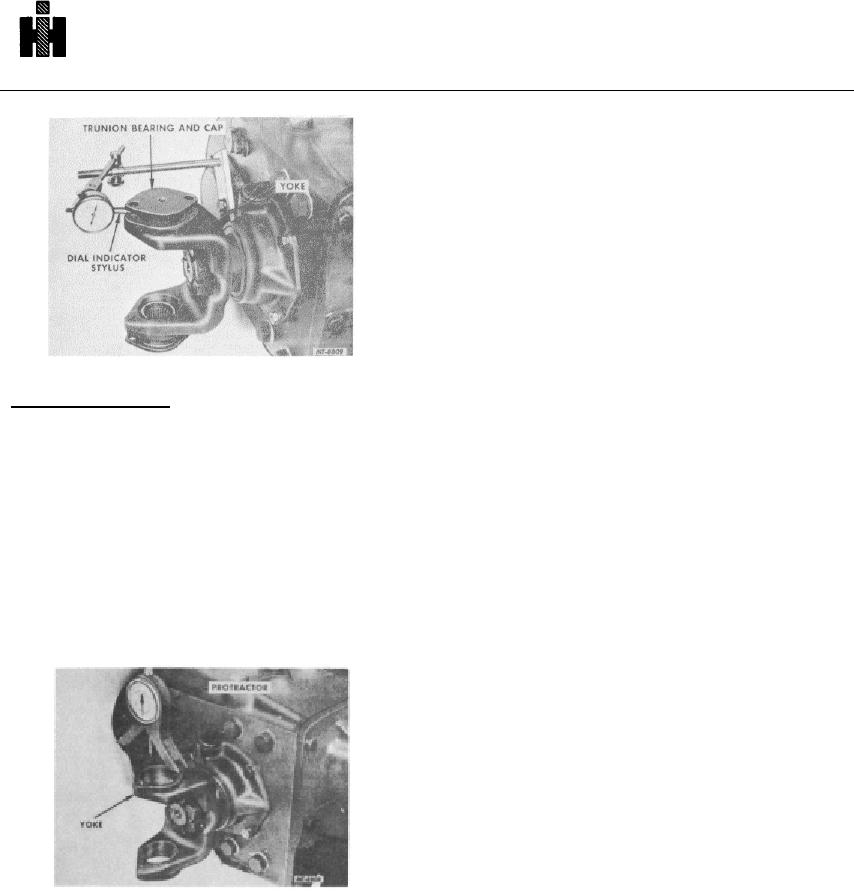

Fig. 19 Checking Yoke Run-Out

yoke are same as for checking a flange; however, a

piece of round bar stock that is a slip fit in the yoke

Yoke Vertical Alignment

bearing bores is used in lieu of a flat bar straight edge.

If a slip fit gauge bar is not available, a piece of

Yoke vertical alignment can be checked at

round stock slightly smaller than the yoke bearing bore

either the top or bottom lug, whichever is most

inside diameter can be used.

accessible.

Position the smaller stock through the bearing bores and

tap a wooden wedge between it and the yoke shaft.

Locate the vehicle on a level floor and using

Check with a protractor or square to see that the bar is

an SE-2067 magnetic base protractor, deter-

exactly 90 degrees to the machined outside face of the

mine the engine angle (same as when checking

yoke lugs.

flange vertical alignment).

Measure the distance between the gauge bar and

straight edge clamped on the frame as when checking

If cap and bearing retainer are separate

flange horizontal alignment.

pieces, remove lock strap and cap. Pull re-

Corrective

measures

for

yoke

horizontal

tainer out so that it extends approximately 1/8"

misalignment are the same as for flange misalignment.

beyond yoke lug.

MULTIPLE DRIVE LINE ALIGNMENT

All vehicles having more than one propeller shaft or

drive line require the same degree of accuracy for

checking each component. This means that the flanges

and yokes of all auxiliary units and tandem drive axles

should be similarly checked.

UNIVERSAL JOINT LUBRICATION

Light- Duty Models

Joints with plugs or fittings: Lubricate under low

pressure every 20, 000 miles. Too much pressure will

damage oil seals. Use Lithium 12-Hydroxy Stearate EP

grease. Joints without plugs or fittings: Every 50, 000

miles clean and inspect joints, repack with Lithium 12-

Fig. 20 Checking Yoke Vertical Alignment

Hydroxy Stearate EP grease. NOTE: Frequent use of

vehicles in off-the-road operations that encounter mud

Place protractor on bearing retainer at right angle to

and water, lubricate or repack joints every 12, 000 miles.

vehicle center line. Rotate yoke until bearing bores are

vertical (dial reads zero). Without turning yoke rotate

protractor 90 degrees, placing it parallel with the vehicle

center line (in line with propeller shaft). Dial

602