PROPELLER SHAFT

TRUCK SERVICE MANUAL

General

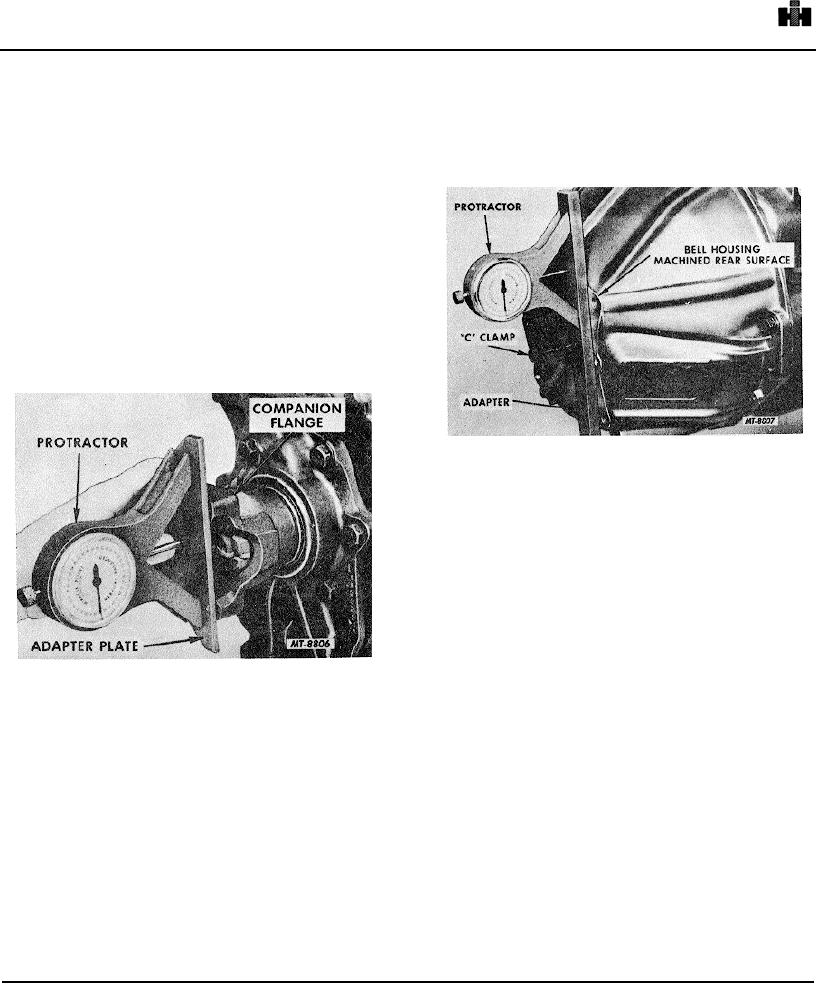

Place an SE-2067 magnetic base protractor on the

When aluminum bell housings are encountered, the

horizontally machined surface of the cylinder head,

protractor will not adhere; therefore, it will be necessary

crankcase oil pan rail or possibly along the flange of the

to either hold protractor firmly or clamp a steel straight

rocker arm cover, Fig. 11. This angle establishes the

edge in a vertical position and place the protractor on the

correct vertical angle for all propeller shaft flanges and

straight edge, Fig. 13. The protractor dial should read 90

yokes.

degrees minus the number of degrees of engine

Read and record the number of degrees of engine

declination.

declination indicated on the protractor dial. This is the

engine angle.

Place transmission shift lever in neutral position.

Rotate transmission mainshaft to place flange C in a

vertical position. Place SE2067 magnetic base

protractor in a vertical position with one leg of protractor

base on flange machined surface as shown in Fig. 12.

Protractor reading should be 90 degrees minus the

number of degrees of engine declination. If readings

differ by more than 1/2 degree, the flange is misaligned

in the vertical plane. In other words, the flange machined

surface is not perpendicular (90) to the engine

crankshaft center line.

Fig. 13. Checking Bell Housing Vertical Alignment Using

SE-2067 Magnetic Base Protractor

If misalignment still exists, it will be necessary to

remove the bell housing and check the vertical alignment

of the flywheel housing (if applicable) using same

checking method as used with bell housing check.

Some engine models require a flywheel housing to

be used between the engine rear machined face and the

bell housing. If previous checks have not eliminated the

vertical misalignment, remove the bell housing and

clutch assembly. The rear machined face of the flywheel

housing can be checked using a straight edge and

Fig. 12. Checking Main Transmission Companion

SE2067 protractor held firmly in a vertical position. The

Flange Vertical Alignment

reading should be 90 degrees minus the number of

degrees of engine declination. In other words, this

If the companion flange run-out is within limitations

surface must be perpendicular (90 degrees) to the

but the vertical alignment is not, it indicates that the

engine crankshaft horizontal center line. Misalignment of

problem lies within the mating surfaces of the flywheel

less than 1/2 degree at this point would indicate that the

housing to engine, bell housing to flywheel housing or

problem lies with the front and rear machined surfaces of

transmission housing to bell housing. Misalignment of

the flywheel housing and bell housing not being parallel

any of these components is highly improbable, since the

or that the front machined surface of the transmission is

mating surfaces are machined to strict tolerances;

not perpendicular to the mainshaft. These conditions

however, since the possibility does exist, it will be dealt

can be readily checked. It should be noted, however,

with herein.

that foreign material such as a piece of an old gasket not

To determine which component is at fault, remove

removed during a previous service operation will result in

the transmission and check the bell housing rear

misalignment of the transmission flange in either a

machined face for vertical alignment. Clean the face of

vertical or horizontal plane, depending upon its location.

all foreign material and place SE-2067 magnetic base

protractor in a vertical position on this face. NOTE:

598