TRUCK SERVICE MANUAL

PROPELLER SHAFT

General

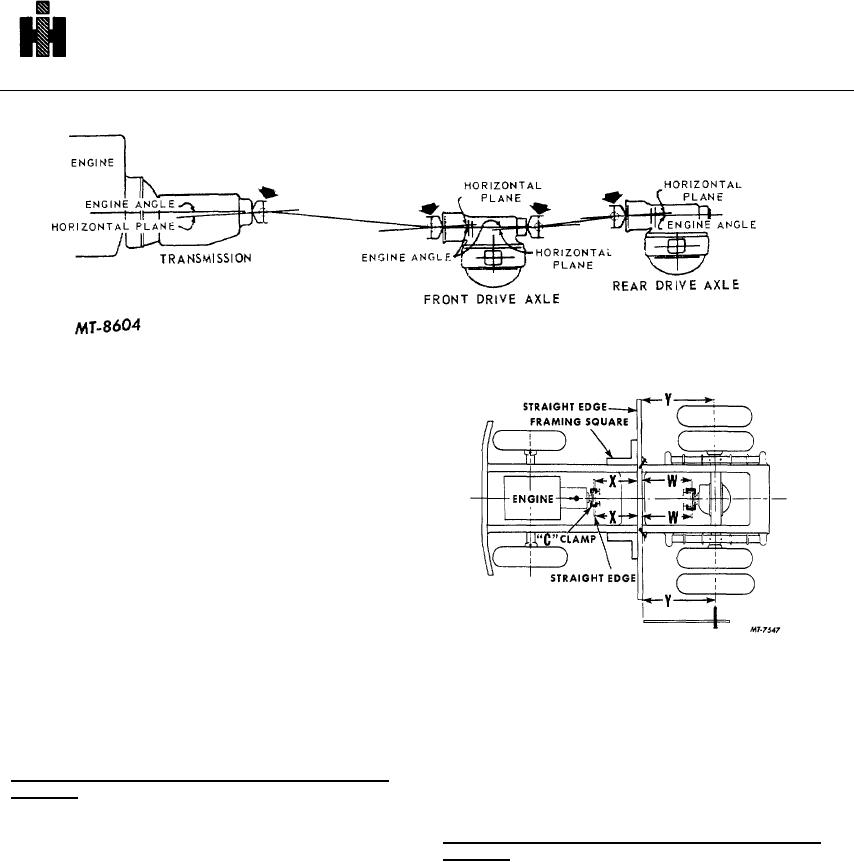

Fig. 16 Rear Axle Pinion Shaft and Engine Crankshaft Horizontal Center Lines Parallel

It should be remembered that even with the "broken

back" drive line, the working angles of both universal

joints are equal; however, the flanges will not be parallel.

This condition is permissible and should provide

satisfactory drive line operation.

To determine the correct vertical angle of a "broken

back" type drive line flange, extend the center line of the

driving (output) and driven shafts. These lines should

intersect at a point exactly midway between the joint

centers, Fig. 3.

Correction of a vertically misaligned rear axle pinion

shaft flange can be accomplished by placing tapered

shims or wedges between the spring pads and the

springs to tilt the pinion shaft up or down. The angle of

the shims or wedges will depend upon the amount of

Fig. 17 Checking Horizontal Alignment of Propeller Shaft

existing vertical misalignment.

Obtain a second straight edge at least 12" longer

Recheck flange alignment after shims or wedges

than the rear wheel track and clamp it at right angles

have been installed.

across the frame side rails. Check this 90 degree angle

NOTE: Be sure when installing wedges or shims

with large framing squares, Fig. 17.

that the same thickness is used at each spring pad

to prevent inducing a strain on the axle housing or

Measure distances "X", Fig. 17, between the two

springs.

straight edges. These two dimensions should be within

Main Transmission Companion Flange Horizontal

1/16" of each other. If they are not, the flange is

Alignment

misaligned horizontally.

The horizontal alignment of all flanges is just as

important as the vertical alignment.

Auxiliary Transmission Companion Flange Horizontal

Place the vehicle on a level floor.

Alignment

Clamp a straight edge on the main transmission

Checking the horizontal alignment of the auxiliary

companion flange so it will project equally from each side

transmission companion flange requires the same

of the flange.

Place an SE-2067 magnetic base

procedure as does the main transmission flange.

protractor on the straight edge to be sure that it is exactly

Measure distance "W", Fig. 17.

horizontal, Fig. 17.

600