TRUCK SERVICE MANUAL

WHEELS, RIMS, TIRES

to clean an injury if a power buffer equipped with a fine

cleaned surface area. Remove all traces of

wire brush is used. Care must be taken not to buff

lubricant, foreign material, etc. Do not use more

through the innerliner. Clean the awl needle and dip in

solvent after buffing.

self-vulcanizing fluid and from the inside of the tire, force

the needle through the puncture until the point extends

The next three steps apply only to the hot patch method.

5. Remove backing from patch and carefully center

beyond the tread (Fig, 15).

it over injury. Place a clamp over patch and

3. Remove the detachable handle from the needle.

tighten clamp only finger tight (Fig. 18).

Cut a 3.175 mm (1/8") strip of filler rubber and

6. Ignite patch and allow it to cool for at least 15

place it into the hole of the needle with the end of

minutes or until cool to the touch. Carefully

the rubber strip extending beyond the needle.

remove metal pan and ashes remaining in tire.

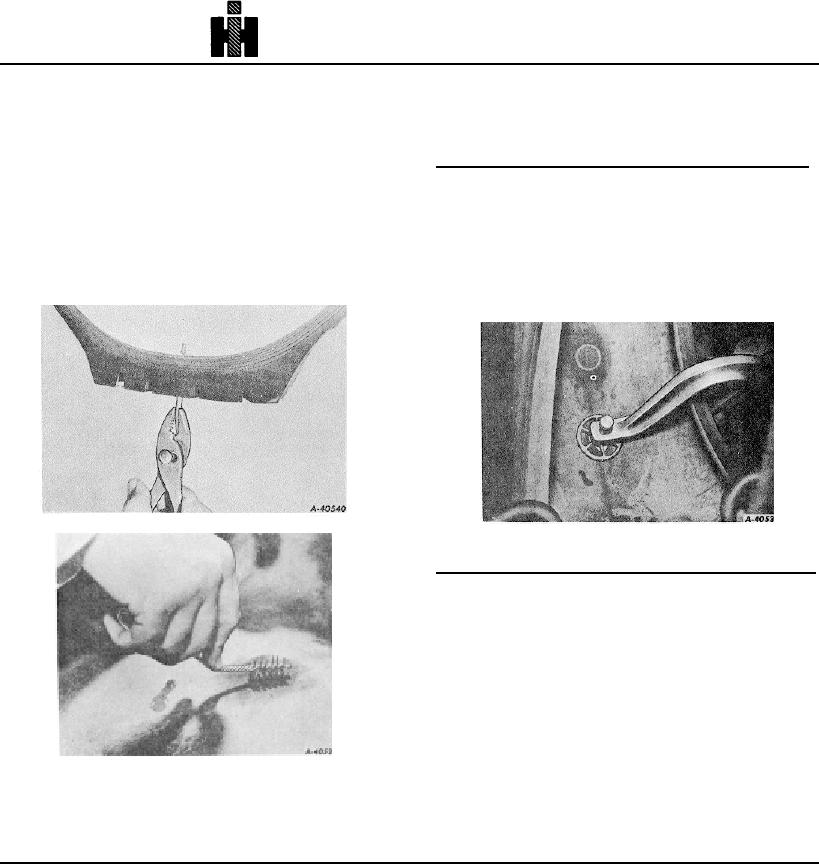

Pull needle through the tire with a pliers (Fig. 16).

7. Remount tire. Inflate to recommended operating

Filler rubber will remain in puncture. Using an

pressure. Then check to make sure injury is

awl, pack excess rubber flush with inside of tire.

sealed.

Fig. 16

Fig. 18

The next three steps apply only to the cold patch method.

8. Apply self-vulcanizing cement over buffed area

and allow it to dry for a minimum of five minutes.

This time factor is important.

9. Remove backing from patch base and place

patch over injury. Press down firmly, especially

at the edges, for good adhesion (and easy

removal of paper cover)(Fig. 19).

10. Remount tire. Inflate to the recommended

operating pressure. Then check to make sure

injury is sealed.

Fig. 17

4. With a wire brush (Fig. 17) or a power buffer,

thoroughly roughen an area about the injury

slightly larger than patch and within previously

858