TRUCK SERVICE MANUAL

WHEELS, RIMS, TIRES

With the improvement in design of both wheel bolt

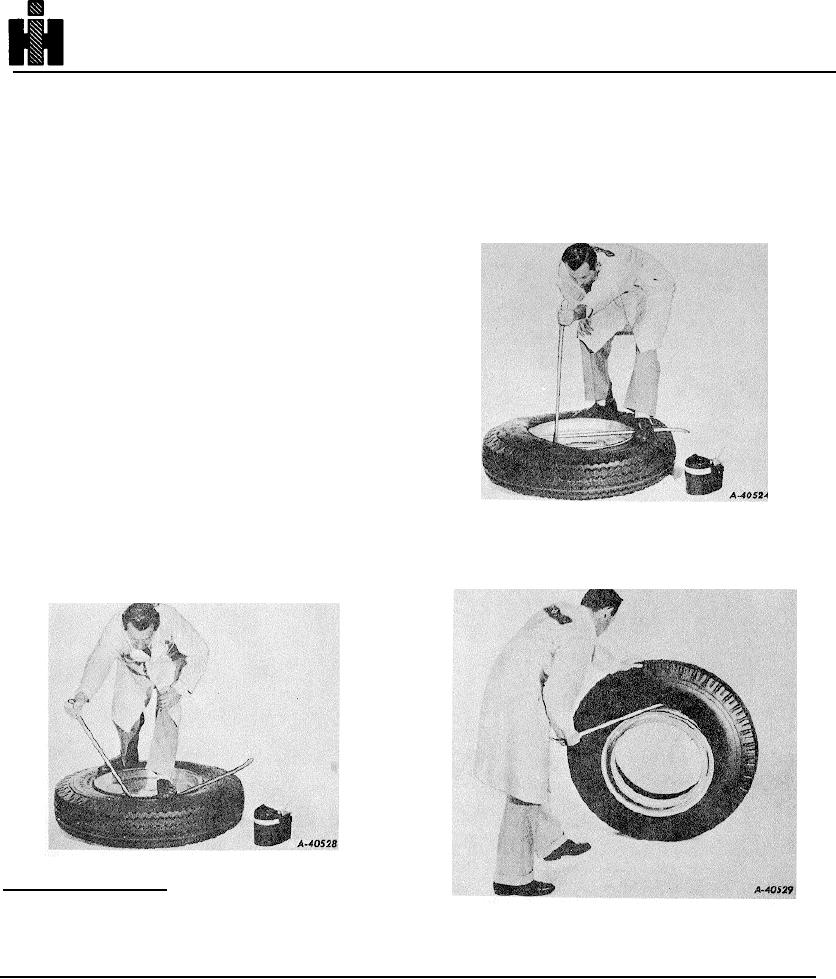

lubricate top bead thoroughly. Insert spoon ends

holes and mounting bolts or nuts the left-hand threaded

of both tire irons between rim and tire bead at

parts are no longer used and right-hand threaded parts

points about 10" apart. While standing on tire, pull

are used at all wheels. To prevent loosening of wheel

end of tire iron to the opposite side of rim so as to

bolts or nuts, cup-shaped depressions are formed in

pry tire bead up and out of rim (Fig. 30).

wheel disc at the bolt holes so that when mating cup-

2.

Hold tool in position with one foot and pull second

shaped nut or bolt is tightened, elastic pressure against

tool toward center of rim (Fig. 31). Progressively

the nut or bolt together with thread friction prevents

work bead off rim in this manner, taking additional

loosening in service. For this reason wheel mounting

bites as necessary.

bolts, nuts and wheel bolt hole surface must not be

lubricated.

It is good practice to tighten wheel nuts daily during

the first 500 miles of service on new vehicles and

anytime wheels have been removed. Regular inspection

periods should be established to assure keeping nuts

tightened.

ONE PIECE DROP CENTER HEAVY DUTY TUBELESS

TIRES (7.00-20 and Up)

The mounting or demounting of heavy duty tubeless

truck tires is accomplished in much the same manner as

light duty or passenger-car type tubeless tires.

Consequently, same precautions for protecting the

sealing edges of the tire beads and rims should be

Fig. 31

observed. Rims used are all of the one-piece drop-

3.

Stand assembly in a vertical position and lubricate

center type whether they are integral with wheel (disc

second bead. At top of assembly, insert straight

type) or demountable (cast type). Because heavier tires

end of tool between bead and back flange of rim at

are less flexible, it is suggested that the special tubeless

about 45 degree angle (Fig. 32).

truck tire tools, which are available, be obtained.

Fig. 30

Dismounting Instructions

Fig. 32

1.

Remove the valve core to completely deflate tire.

With tire lying flat on the floor, loosen beads from

rim seats by walking around on tire with heels at

points close to rim. With wide side of rim down,

861