TM 5-3805-254-20-1

ORGANIZATIONAL TROUBLESHOOTING - CONTINUED

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

WARNING

Parts of brake assembly will be coated with asbestos dust. Breathing this dust may be hazardous to your

health. Use filter mask approved for use against asbestos dust. Never use compressed air or dry brush to

clean these assemblies. Dust shall be removed using industrial type vacuum cleaner equipped with high

efficiency filter system. Clean dirt or mud from brake assemblies with bristle brush or cloth, and water.

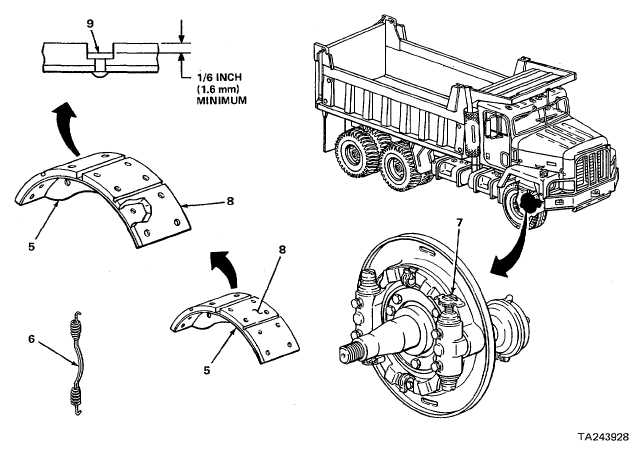

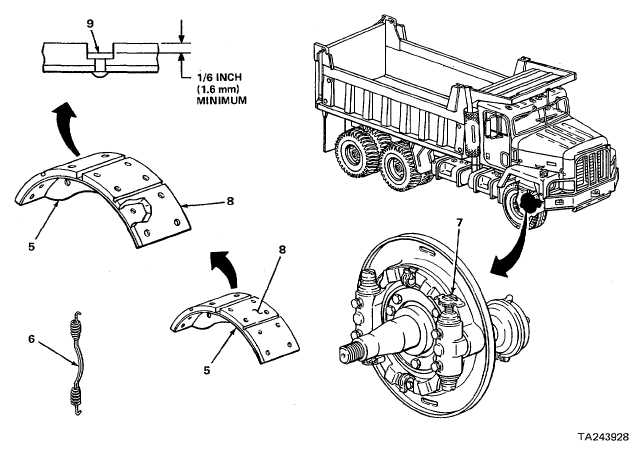

Step 7.

Check brakeshoes (5) and mounting hardware for damage as follows: inspect brake springs (6) for

cracks, breaks, distorted ends, or stretched coils. Inspect adjusting screw rings (7) for missing or

broken teeth or binding condition. Inspect brakeshoes (5) for oil soaked, cracked, burned, or

chipped lining (8). Using tire tread depth gage, check that lining (8) thickness is more than 1/16inch

(1.6 mm) above rivets (9).

If brakeshoes (5) and mounting hardware are damaged, replace (page 2-947).

2-355