TM 5-3805-254-20-1

ORGANIZATIONAL TROUBLESHOOTING - CONTINUED

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 6.

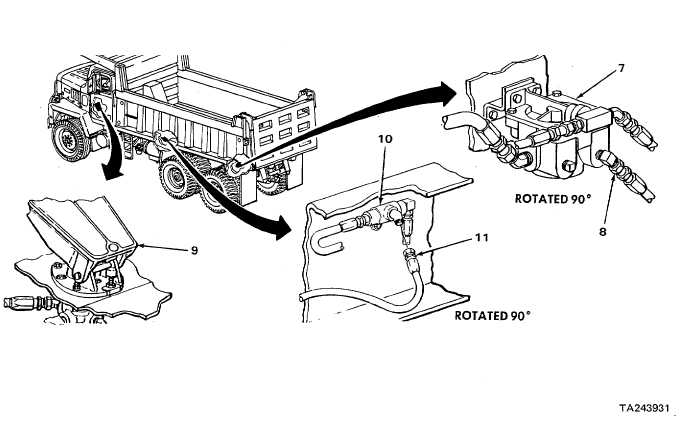

Check front relay valve (7) for input air pressure as follows: using 1 1/4-inch and 1 1/16-inch open-

end wrenches, loosen input hose fitting (8) six turns. Have assistant press down brake pedal (9),

listen for hissing noise at input hose fitting (8), release brake pedal (9).

a. If hissing noise is heard at input hose fitting (8), tighten using 1 1/4inch and 1 1/16-inch

open-end wrenches, replace, notify Direct Support Maintenance.

b. If hissing noise is not heard at input hose fitting (8), tighten using 1 1/4-inch and 1

1/16-inch open-end wrenches, and go to step 7.

Step 7.

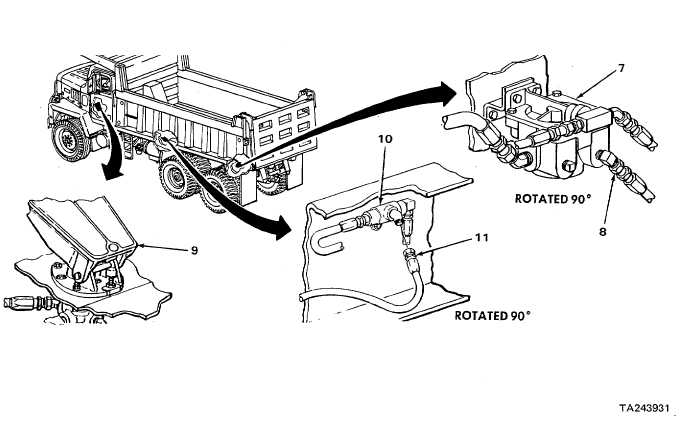

Check double check valve (10) for output air pressure as follows: using 3/4-inch open-end wrench,

loosen output hose fitting (11) six turns. Have assistant press down brake pedal (9), listen for

hissing noise at output hose fitting (11), release brake pedal (9).

a. If hissing noise is not heard at output hose fitting (11), tighten using 3/4-inch open-end

wrench, and go to step 8.

b. If hissing noise is heard at output hose fitting (11), go to step 9.

2-359