TM 5-3805-254-34

6-33.

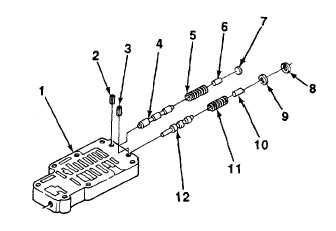

LOW SHIFT VALVE REPAIR.

This Task Covers:

a.

Disassembly

c.

Assembly

b.

Cleaning and Inspection

Initial Setup:

Equipment Conditions:

Materials/Parts:

• Low shift valve removed (see paragraph 6-13).

• Hydraulic fluid (Item 7, Appendix B)

Tools/Test Equipment:

• Dry cleaning solvent (Item 23, Appendix B).

• General mechanic's tool kit

• Field automotive shop set

General Safety Instructions:

• Dry cleaning solvent is flammable and must not be used near open flame. Use only in a well-ventilated area.

• Compressed air used for cleaning or drying purposes, or for clearing restrictions, should never exceed 30 psi (207

kPa).

a.

DISASSEMBLY

1.

Press inward on plug (7) and remove pin (2).

2.

Release pressure and remove plug (7), valve

stop (6), spring (5), and relay valve (4) from low

shift valve body (1).

3.

Mark position of adjusting ring (8) in low shift

valve body (1) for assembly.

4.

Press inward on adjusting ring (8) and remove

pin (3).

5.

Release pressure and remove adjusting ring (8),

washer (9), valve stop (10), spring (11), and low

shift valve (12) from low shift valve body (1).

b.

CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, Is toxic and flammable. Always wear protective goggles and

gloves, and use only In a well-ventilated area. Avoid contact with skin, eyes, and clothes, and DO

NOT breathe vapors. DO NOT use near open flame or excessive heat. The solvent’s flash point Is

100°F-138°F (380C-590C). If you become dizzy while using cleaning solvent, Immediately get fresh

air and medical help. If solvent contacts eyes, Immediately wash your eyes and get medical aid.

1.

Clean metal parts with dry cleaning solvent.

TA703866

6-149