TRUCK SERVICE MANUAL

AXLE-REAR

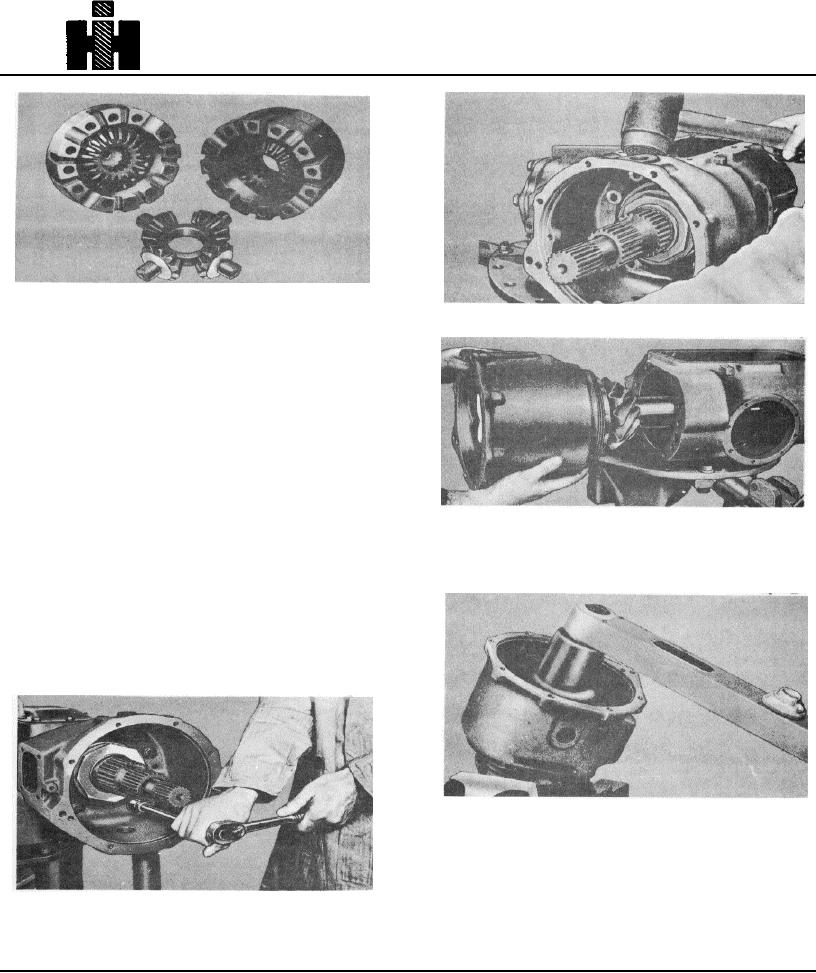

F. Disassemble case sections and remove spider,

pinions, side gears and thrust washers. Do not

E. Lightly tap on the top edge of housing with a

remove the bearing from the case unless

rawhide hammer to loosen it from carrier.

replacement is necessary.

G. If it is necessary to replace the outer bearing in

the cover, drive the oil seal from the cover and

remove bearing.

REMOVE AND DISASSEMBLE HYPOID PINION AND

QUILL, BEARING AND HOUSING ASSEMBLY

A. Remove shift shaft housing cap screws and lock

washers. Remove shift shaft housing assembly.

F. Remove housing and pinion quill assembly.

Wire shim pack to carrier to aid reassembly.

B. Disassemble and remove shift lever attaching

G. Clamp the pinion and quill assembly in a copper-

nut, button, lever, cup and spring. Body fit bolt

jawed vise and straighten pinion bearing outer

should not be removed.

(am) nut lock washer.

NOTE: Shift unit may be single or double line

vacuum, air or electric.

C. Remove inter-axle differential shift collar from

pinion quill assembly.

H. Remove the pinion bearing outer nut and lock

washer, inner adjusting nut lock and inner

adjusting nut.

A hard wood wedge inserted between the

teeth of the hypoid pinion and hypoid gear will

prevent the gears from turning while loosening

D. Cut housing cap screw or stud nut lock wire.

and tightening the bearing adjusting and jam

Remove cap screws or stud nuts. Also remove cross

nuts when the gears are assembled in the

shaft cover and carrier inspection cover.

carrier.

29