TRUCK SERVICE MANUAL

AXLE-REAR

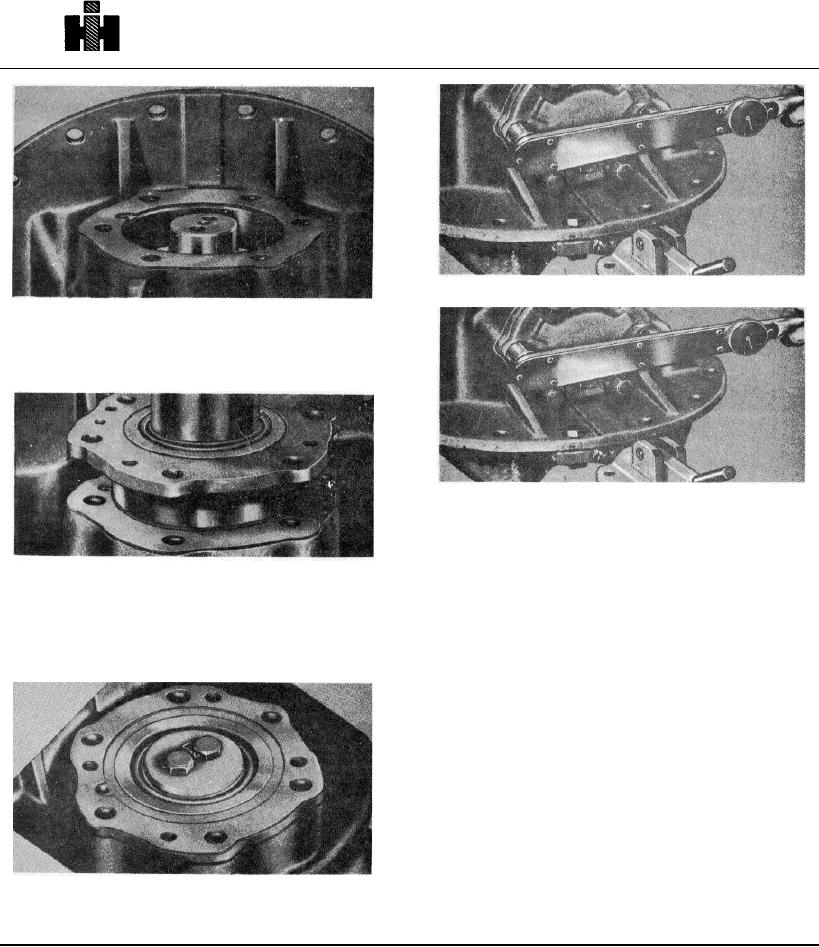

M. Assemble bearing cage cover, lock washers and

capscrews. Tighten to specified torque.

I. Install original shim pack (which controls gear back

lash) over cross shaft opening in carrier. Apply

colloidal graphite lubricant to cross shaft bearing

journal. Place cage in carrier over shim pack,

carefully aligning oil holes in cage with oil holes in

drive unit. Press bearing cage part way into carrier.

N. Measure cross shaft bearing preload torque. Wrap

strong cord around spur pinion and pull on horizontal

line with pound scale.

The preload torque specification for tapered

roller bearings mounted close together in the bearing

J. Press inner bearing part way onto cross shaft, then

cage is 5 to 15 pound inches (new and serviceable

install outer bearing and cup onto cross shaft. Use a

used bearings).

suitable sleeve and press bearings and cage

completely into carrier.

Example: Assume spur pinion diameter is 4",

the radius is 2'; and with 5 pounds pull on the scale,

K. Assemble bearing retainer plate with 2 capscrews.

preload torque is 10 pound inches.

Tighten capscrews to specified torque and lock with

soft iron wire.

Read rotating pounds pull, not starting pounds

pull.

If preload torque is not within 5 to 15 pound

inches, add shims between cover and cage to

decrease, or remove shims to increase cross shaft

bearing preload torque.

If the pinion, quill and through shaft assembly was not

disassembled disregard re-assembly section Pagesl8, and 19

and temporarily install the pinion, quill and through shaft into

carrier (Page 19, Item H) for tooth contact and backlash check.

See backlash and tooth contact section, Pages 21 and 22.

L.

Install bearing cage cover original shim pack

Continue re-assembly by installing the shift unit, Page 19. If

(which

controls

tapered

bearing

preload).

the pinion, quill and through shaft assembly was

disassembled, continue with Item "A" Page 18.

37