TRUCK SERVICE MANUAL

AXLE-REAR

(NEW GEARS)

Tooth contact may be checked by applying a thin even

coat of lightly oiled red lead with a small brush to both drive

and coast sides of a dozen teeth of the gear. When the pinion

is rotated the red lead is squeezed from the gear teeth by

pressure of the pinion teeth leaving areas the exact size,

shape and location of the contacts. Sharper, better defined

areas of contact can be obtained by applying rolling resistance

to the gear providing the gear is not forced out of location

during the checking operation.

Use the smallest amount of the lead and oil mixture that

will render good impressions. The drier the mixture the better

the impressions. Clean the material from the gear and pinion

teeth when the operation is complete. Always judge tooth

contact by noting pattern on the drive side of the gear teeth.

The coast side pattern should be correct when the drive side

pattern is correct.

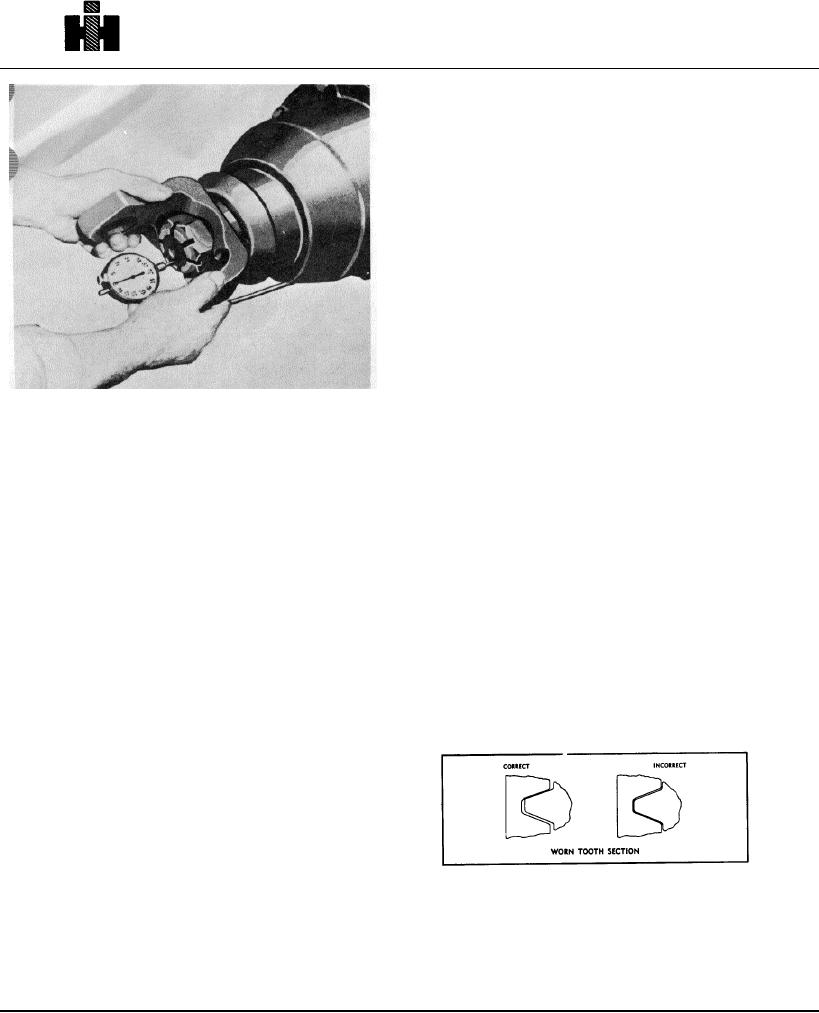

3. While watching the indicator push inward on the

IMPORTANT: When backlash amount is not specified, set

flange or yoke and roll it back and forth until the

backlash to the following:

indicator stops changing. Make a note of this reading.

In a similar manner, pull outward and roll the flange or

STDD

yoke until the indicator again stops changing. The

Forward Rear -.005 to .015

difference between this reading and the inward

Rear Rear -.005 to .015 SUDD

reading is the adjustment condition.

Forward Rear -.005 to .015

Rear Rear -.020 to .026, however, .010 should be used

4. Correct to .003 to .005 end play if necessary by using

for establishing tooth contact pattern, than opened

thicker or thinner spacer.

to .020 to .026.

E. Remove yoke or flange and input nut.

RE-CHECK BACKLASH (USED GEAR SETS)

F. Install oil slinger if used, reinstall yoke or flange, input

Generally, if original gears are being re-installed in

washer and nut. Tighten nut to recommended torque

assembly, red leading of teeth will not indicate the same

value.

contact as new gears and can be misleading. Gears that have

been in service for long periods form running contacts due to

SHIFT SHAFT ADJUSTMENT

wear of teeth. Therefore, the thickness of the original shim

pack plus approximately .015" additional shim stock should be

1. Apply air or vacuum to move shaft to its full travel to

maintained to check gear lash. In the event that gear lash is in

"lock" interaxle differential.

excess of maximum tolerance, as stated under gear

adjustment, reduce gear lash, only in the amount that will avoid

2. Turn adjusting screw (in rear of unit) to contact shift

overlap of the worn tooth section.

shaft.

3. After contact with shaft has been made turn adjusting

screw in 3/4 of a turn.

4. Lock adjusting screw in position with jam nut.

ESTABLISH TOOTH CONTACT AND GEAR

Gear lash can only be reduced to a point of maintaining

BACKLASH

smooth rotation of bevel gears.

Hypoid gear first reduction units have a single shim pack

Smoothness or roughness can be noted by rotating bevel

between the pinion cage and carrier or interaxle differential

gear. If a slight overlap, as illustrated, takes place at worn

housing and carrier to control pinion position.

tooth section, rotation will be rough. Generally with the original

A shim pack between the cross shaft bearing cage flange and

gears,

tone

should

be

satisfactory.

the carrier controls the position of the first reduction hypoid

gear in all top mounted double reduction drive units.

41