TRUCK SERVICE MANUAL

AXLE-REAR

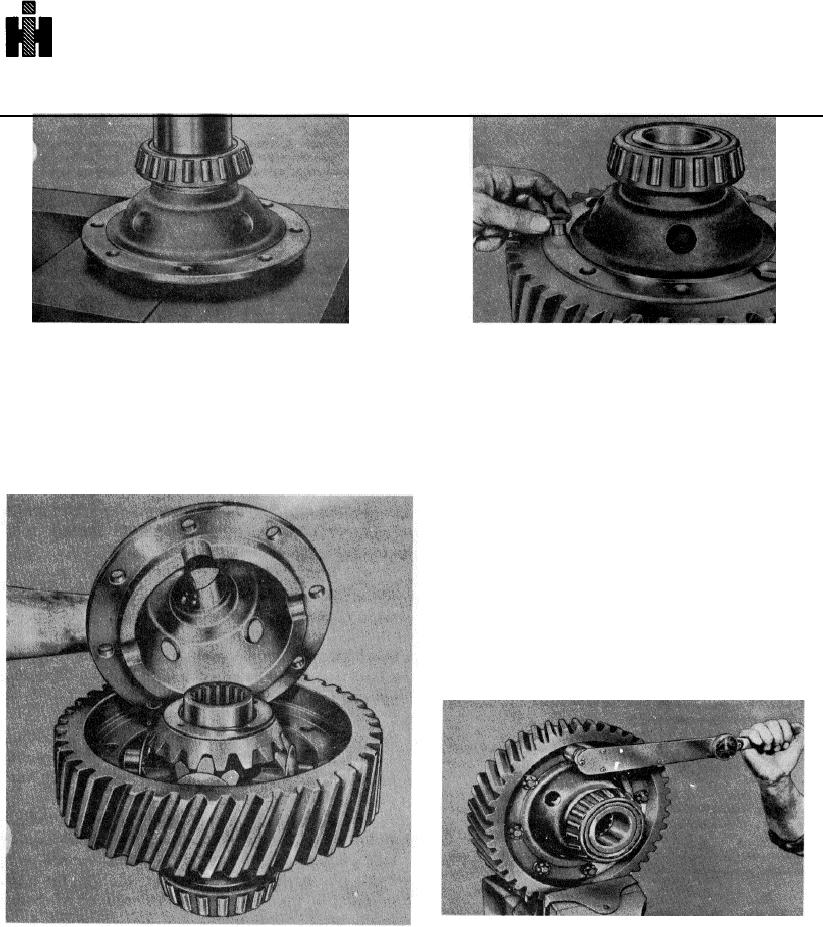

ASSEMBLE AND INSTALL AXLE DIFFERENTIAL

D. Install remaining differential case bolts so heads are

A.

Press differential bearings firmly against case

locked by machined relief in case half. Be sure case

shoulders. Coat inside of case and all differential parts

halves are assembled to gear so there is adequate nut

with specified rear axle lubricant.

clearance. Check clearance in carrier before completing

assembly

B. Assemble differential case half and gear. Install side

gear

thrust washers, side gears and differential pinion gears,

When a new gear or a new differential case is installed

thrust washers and spider.

the case holes must be line reamed with the gear in

order to assemble the parts using the correct size rivets

or bolts. Align the case halves and hold case and gear

assembly together with 4 bolts and nuts. Line ream the

holes. Thoroughly clean the parts before assembly.

Hold differential case assembly together with 4 bolts

when riveting the parts together. Use a rivet set that will

shape the formed head 1/8" larger in diameter than the

rivet hole. The formed head height should not be more

than 1/16" lower than the preformed head. A lower

formed head indicates high riveting pressures that may

distort the case and cause gear eccentricity.

C. Note cast alignment marks and assemble opposite

E. Tighten bolt nuts to specified torque and lock wire or

case half. Hold assembly together with 4 bolts and nuts

cotter in place

and check for free rotation of parts.

43