TRUCK SERVICE MANUAL

BRAKES-AIR

REMOVING AND REBUILDING DESICCANT

SEALING PLATE

Before the desiccant cartridge can be replaced

or rebuilt the desiccant sealing plate must be removed.

It is recommended that all non-metallic parts be replaced

when the plate is removed. In the past, three methods

have been employed to secure the desiccant sealing

plate to the desiccant cartridge; a Tru Arc retaining ring,

two special thin nuts and the latest method a single hex

lock nut. Removing the securing device will permit the

desiccant plate to be separated from the desiccant

cartridge. After removing the desiccant cartridge:

1. Remove the two o-rings from the desiccant plate and

discard them.

2. Remove the ball check valve retaining clip and

remove and discard the rubber ball valve.

3. Clean the desiccant plate thoroughly using a quality

commercial solvent making sure the purge orifice

and check valve seat are clean.

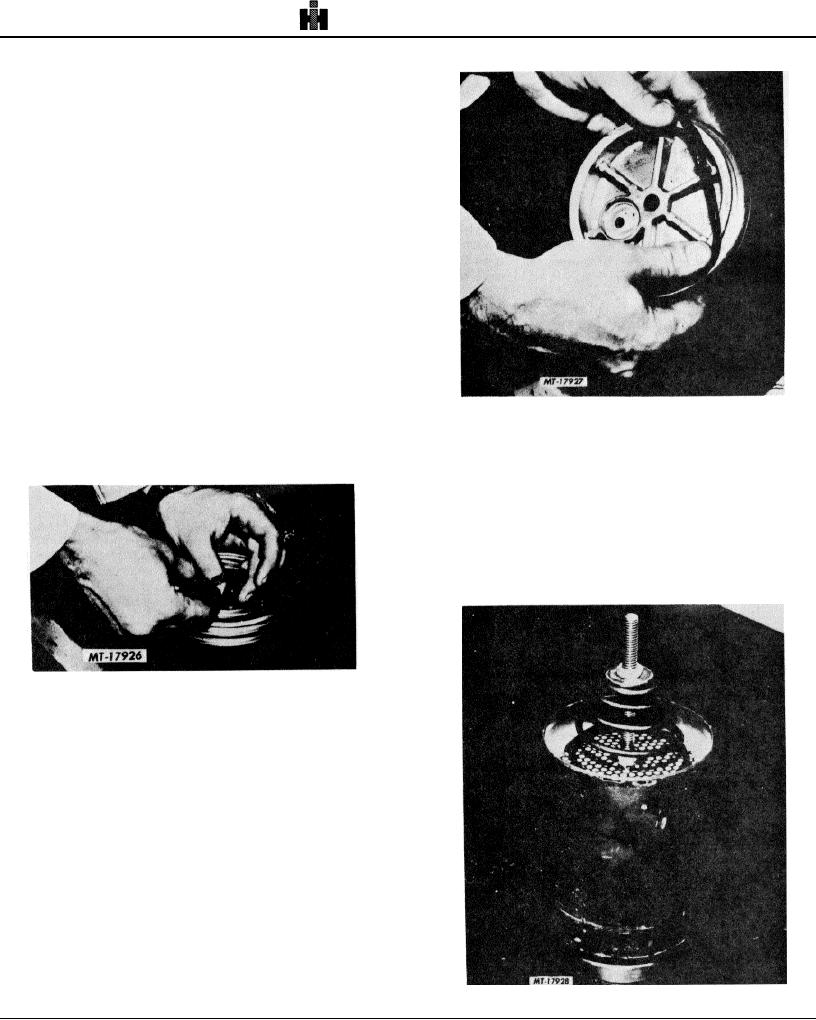

Fig. 8. Installing O-Rings

4. Install new ball check valve and replace the retaining

ing instructions), the cartridge removed from the air dryer

clip and screw (Fig. 7)

may be discarded after the desiccant sealing plate is

removed.

The current revision replacement desiccant

cartridge is shown in Fig. 9. All prior revisions of the

cartridge with interchange with no modifications to either

air dryer.

Fig. 7 Installing Check Valve

5. Thoroughly lubricate the two new orings and install

them in their respective grooves in the purge plate

(Fig. 8).

6. Set the desiccant sealing plate

aside

for

reinstallation on the desiccant cartridge.

REPLACING DESICCANT CARTRIDGE

If the desiccant cartridge is to be replaced as an

assembly rather than rebuilt (see desiccant cartridge

rebuild-

Fig. 9 Replacement Desiccant Cartridge

178