TRUCK SERVICE MANUAL

BRAKES-AIR

7. Discard the piston O-ring, the purge valve and the

piston return spring.

8. Wash all remaining parts in a commercial solvent

making sure all surfaces, bores, ports and passages are

clean and dry before reassembly.

NOTE: The heater and thermostat assembly in

the AD-2 end cover are non-serviceable. Do not

remove the thermostat cover.

Should this

assembly become defective, the end cover must

be replaced.

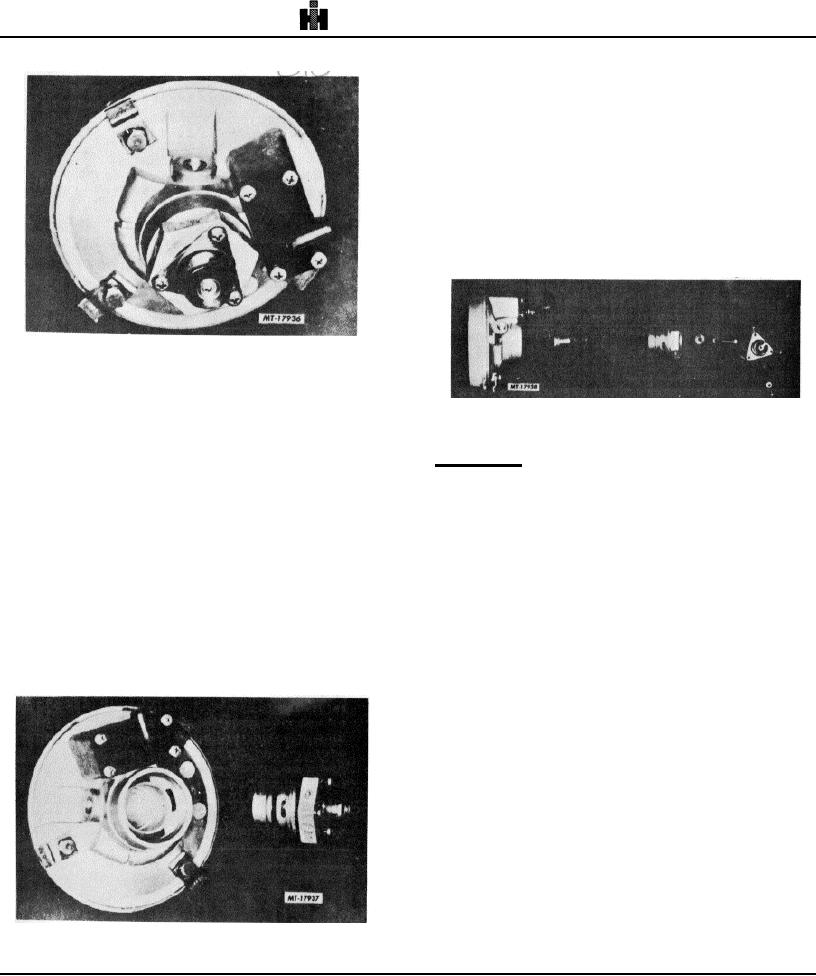

Fig. 17 AD-2 End Cover Assembly

2. Remove the single 6-32 screw securing the exhaust

diaphragm and separate the diaphragm, washer and

Fig. 19 Purge Valve Assembly Disassembled

screw. Discard the diaphragm.

Reassembly

3. Remove the three No. 6-32 screws securing the

exhaust cover and remove the exhaust cover.

1. Lubricate the piston O-ring and install it on the

piston.

4. Remove the purge valve assembly, the large hex

cap nut from the end cover and discard both O-rings

2. Lubricate the piston bore and install the piston.

around the cap nut.

3. Install the purge piston return spring and piston.

5. Using a 7/16" socket wrench and a large

screwdriver, remove the 1/4"20 hex head cap screw

4. Install the purge valve in the large cap nut so that the

which holds the assembly together.

rubber portion rests on the metal seat of the cap nut.

6. Separate capscrew, purge valve, purge valve piston

5. Secure the valve to the piston using the 1/4"-20

and the piston return spring.

capscrew and lockwasher and torque to 5.5 N.m (50

in. lbs.).

6. Lubricate and install the two cap nut O-rings.

7. Lubricate the cap nut threads and the cap nut bore of

the end cover and install the cap nut; torque it to

19.8 27.5 N.m (180 250 in. lbs.).

8. Secure the exhaust diaphragm to the exhaust cover

using the No.

6-32 phillips head screw and

diaphragm washer.

9. Secure the exhaust cover to the purge valve hex

head cap nut using the

Fig. 18 AD-2 End Cover Assembly with Purge Valve

Assembly

182