TRUCK SERVICE MANUAL

BRAKES-AIR

Wherever brake linings or blocks are worn to within 1/16"

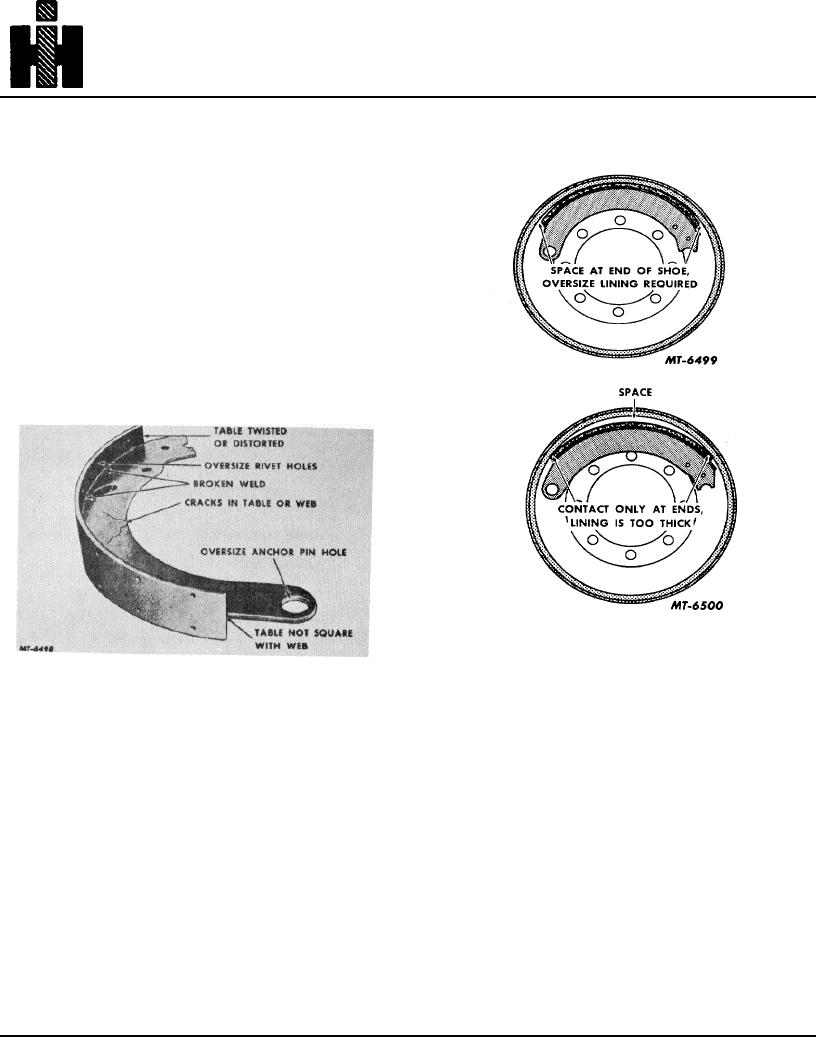

oversize lining is required (Fig. 12. If lining selected is

of rivets, the brake shoes must be removed and relined.

too thick, only the ends of the lining will contact the drum.

It is recommended that all the brakes be relined at the

see Fig. 13.

same time since this will maintain balanced braking on

the vehicle. If complete replacement is not desirable or

necessary, be sure that all lining on one axle (both sides)

is replaced at the same time.

When removing worn lining from shoes, drill out old

rivets if possible to prevent distorting shoe table. After

the old linings are removed from the shoes, the shoes

should be cleaned and buffed to remove all dirt and

grease. Grease is one of the greatest deteriorating

agents of lining.

Fig. 12 Lining Selected too Thin

Examine shoes carefully and discard those which have

any defects as shown in Fig 11.

Fig. 13 Lining Selected Too Thick

The lining must be installed on the shoe so that it fits

Fig. 11 Defects to be Looked for on Brake Shoe

smoothly and evenly, contacting the shoe throughout the

entire radius. If gaps occur between the rivets, difficulty

Discard used lock washers after removing lining bolts.

will be met in adjusting the brakes in that "spongy" or

Use new washers when installing new lining. Replace

rubbery pedal may occur which makes satisfactory brake

bolts and nuts if signs of distortion or wear are present.

application impossible.

Care should be used in selecting the correct thickness of

To insure complete contact and avoid gaps between

lining for each brake shoe and drum. Usually the

lining and shoe, secure lining to shoe with "C" clamp so

standard thickness will be used. If the drum has been

that rivet or bolt holes are in alignment. Position "C"

turned or become worn, increasing the diameter,

clamp as close to the holes as possible, clamping the

oversize lining may be required.

lining firmly in place.

If it is not known how much material has been removed

When securing brake lining to shoes, start with the

from the drum during the turning operation, the following

center rivet or bolt and work toward the ends as shown in

simple test may be used to help select the proper lining.

Fig. 14. When securing brake block lining to shoe, use

the sequence as shown in Fig. 15. Always use new lock

Hold standard size lining snugly to the shoe, position it

washers when installing bolt on lining and tighten nuts to

against the inner surface of the drum, forcing it into

20-25 ft. lbs. torque.

contact with the drum surface. The lining is now in the

same position as during a brake application. If space is

noted at the ends of the shoe (shoe can be rocked),

189