TRUCK SERVICE MANUAL

BRAKES-AIR

The anchor pins are designed to withstand 190 all the

braking force of slowing or stopping the vehicle.

The anchors should be inspected for signs of wear. In

most cases rust will be the factor in servicing brake

anchors. Clean all dirt and rust from anchors and coat

them with a very light coat of "Lubriplate 110' or

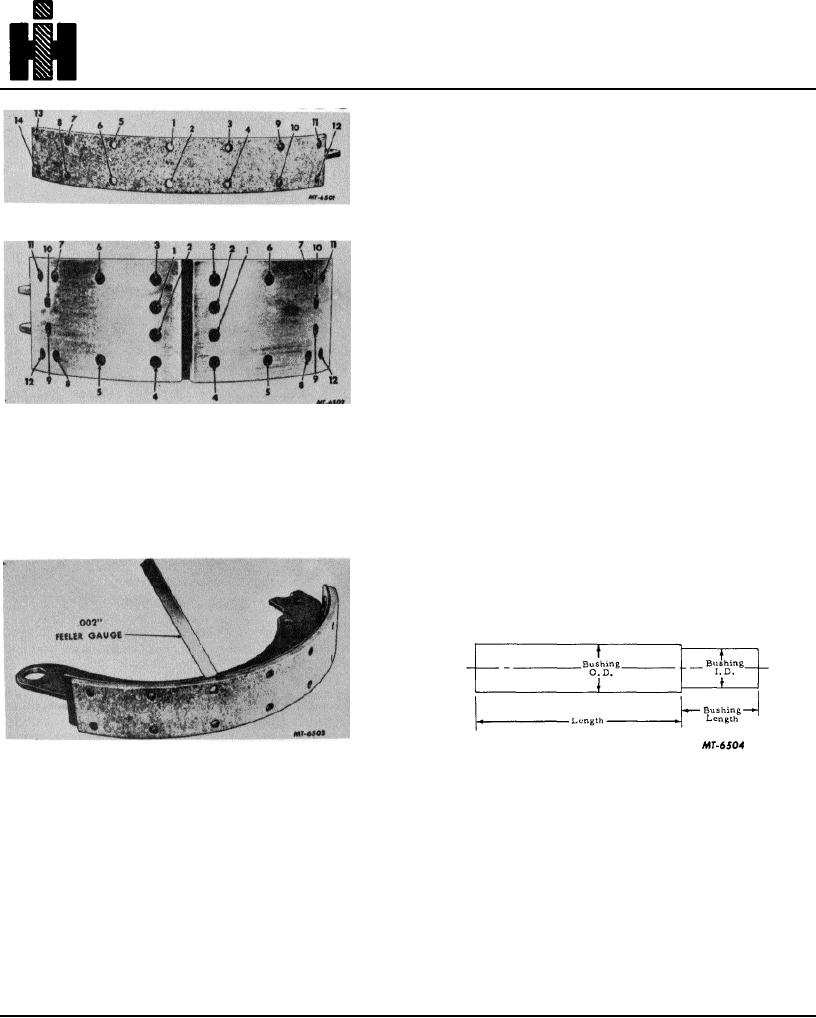

Fig. 14 Sequence in Securing Brake Lining to Shoe

equivalent.

CAMSHAFT, BUSHINGS AND FOLLOWERS

The camshaft is actuated by the movement of the slack

adjuster. The rotating movement of the cam forces the

shoe followers away from the cam, thus forcing the

shoes into contact with the drum.

Removal procedure for camshaft assembly is covered in

the Brake Disassembly procedure. When removing the

camshaft from the backing plate or spider, note the

position of spacing washers to assure correct

Fig. 15 Sequence in Securing Brake Block Lining to

reinstallation, Do not remove camshaft bushings from

Shoe

spider and/or mounting bracket unless replacement is

necessary.

When riveting linings, use a roll set to up-set the rivets.

A star set may split the tubular end of rivet and prevent a

NOTE: Do not interchange right and lefthand camshafts.

tight fit. After the lining is installed, check tightness of

lining to shoe, with a 002" feeler gauge. Gauge should

If camshaft bushings or needle bearings must be

not penetrate past rivets or bolts, Fig. 16.

replaced, a suitable tool (remover) can be made locally

as shown in Fig. 17.

Apply Lubriplate 110 or equivalent to outside diameter of

bushings to assist in pushing them into position

Fig. 16 Checking Tightness of Lining

Fig. 17 Recommended Type of Camshaft Bushing

Removing Tool

After installing the new lining on the shoes, the lining

should be ground in a true radius to fit the drum

BRAKE CHAMBERS

diameter. A brake shoe grinder is provided on brake

reline (SE-1272) which is designed to dress the lining in

Brake chambers (Fig. 18) transform the energy of

a true radius and fit the drum diameter. This grinder

compressed air into mechanical force and motion to

swings the shoe in an arc across the surface of an

apply the brakes. One chamber is used at each wheel to

abrasive wheel.

operate the brakes.

ANCHOR PINS

Air pressure entering the brake chamber, Fig. 18,

behind the diaphragm forces the diaphragm and push

The anchor pins provide a point where the shoes can be

rod outward, rotating the slack adjuster, brake camshaft

secured to the backing plate or spider and also permit

and cam applying the brakes. The higher the air

positioning the shoe in respect to the drum.

pressure admitted to the chamber, the greater the force

190