BRAKES-PARKING MOTOR TRUCK SERVICE MANUAL

DESCRIPTION

The spring actuated tandem-type parking brake

consists of a tandem-type cylinder connected through the

air brake slack adjuster and brake camshaft to the wheel

brake shoes, Fig. 1.

Fig. 1 Typical Installation of Spring Actuated Parking

Brake.

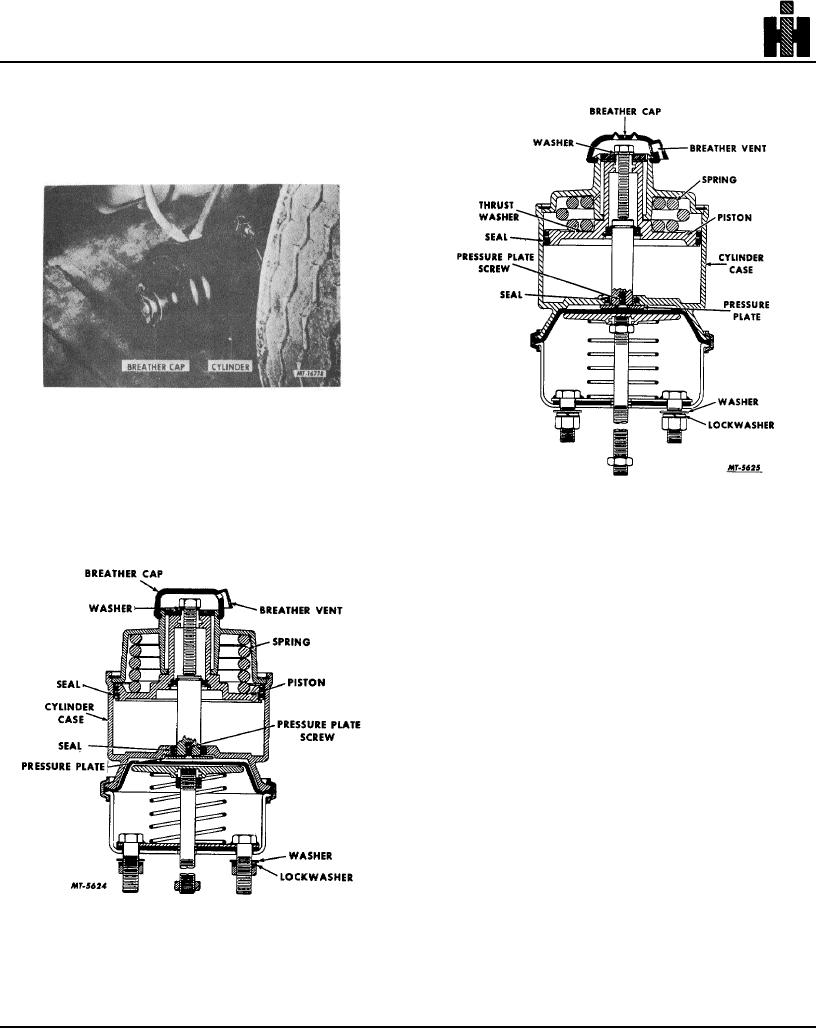

The cylinder assembly is divided into two sections.

One section is a conventional air brake chamber. The

second section is the spring brake section. This section

Fig. 3 Type 30 Chamber.

contains a powerful spring which is compressed by air

pressure, Figs. 2 and 3.

loaded cylinders. Upon reduction of air pressure in the

cylinders, the springs apply the rear brakes through

linkages connected to the rear slack adjusters.

To release the parking brake, the driver operates the

control valve to apply air pressure to the parking brake

spring loaded cylinders, thereby, compressing the

springs and releasing the rear wheel brakes.

Upon loss of air pressure or reduction of air pressure in

the vehicles air system, the parking brakes will

automatically apply, thereby, providing an emergency

brake.

In the event of a failure in the service brake system,

the spring parking brakes can be applied.

The parking brake cylinders differ from the service brake

cylinders in, that the parking brake cylinders apply the

brakes by spring pressure and release them by air

pressure. The service brake cylinders apply the brake

with air pressure and release them by spring pressure.

The parking brake unit requires approximately 60 to

65 psi air pressure to be released. At approximately 70

to 80 psi, the springs are fully compressed.

To release the spring brakes (manual

Fig. 2 Type 20 and 24 Chambers.

OPERATION

To apply the spring parking brake, the driver

operates a control valve which exhausts the air pressure

from the spring

229