MOTOR TRUCK SERVICE MANUAL BRAKES-PARKING

emery cloth (abrasive side against press and tool) to

serve as a nonslip pad between the press ram and tool,

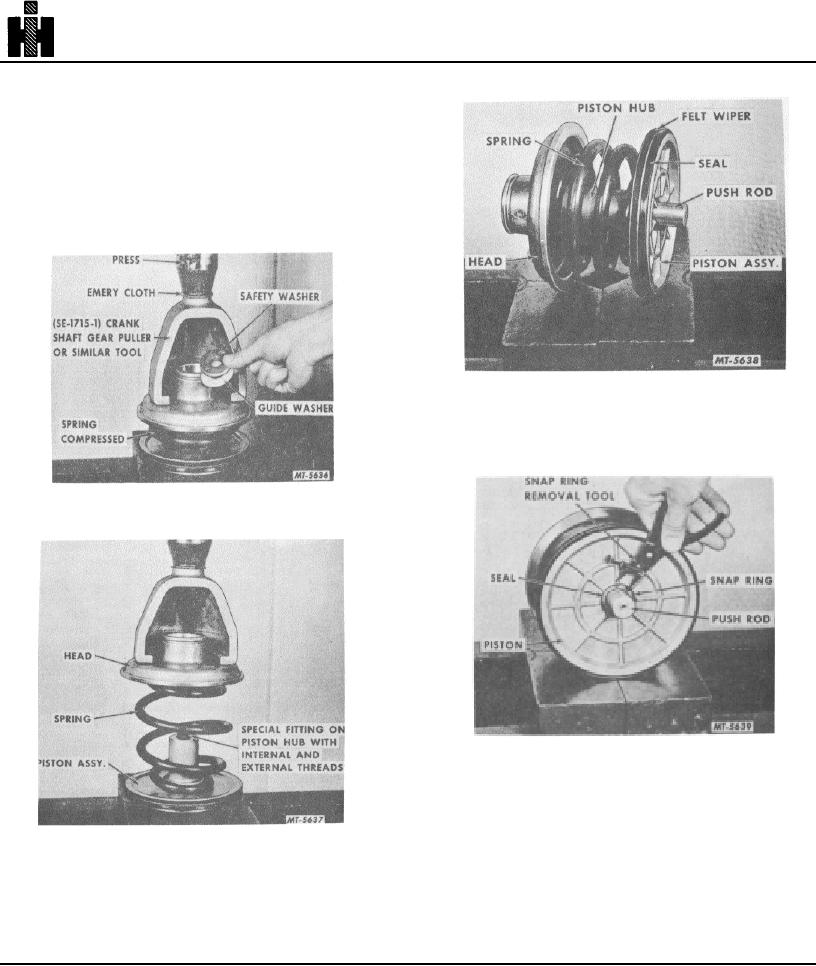

Fig. 14. Depress assembly as shown in Fig. 14.

Use punch, loosen safety washer (counterclockwise for

removing). Remove safety washer and guide washer,

Fig. 15. The safety washer retains the head, spring and

piston assembly. Relax press gradually, Fig. 16. This is

the correct way the head, spring or piston can be

disassembled.

Fig. 17 Piston, Spring and Head Assembly.

Examine push rod for stratches and replace if

damaged.

Fig. 15 Removing Safety Washer and Guide Washer.

Fig. 18 Push Rod Seal Removal.

Remove snap ring from piston and replace push rod

seal if damaged, Fig. 18. Reinstall snap ring, Inspect

push rod seal in bottom of brake chamber housing. If

damaged or worn, replace with new seal assembly. A

Fig. 16 Head, Spring and Piston Assembly with Press

groove is machined directly into the housing for retaining

Relaxed.

the seal.

Clean inside of chamber and all components with a

CLEANING, INSPECTION AND REPAIR

clean solvent before reassembly.

Examine and clean piston felt wiper and seal.

Replace either or both if damaged or worn, Fig. 17.

234