MOTOR TRUCK SERVICE MANUAL

COOLING SYSTEM

GENERAL

COOLING SYSTEM

PREFACE

the filler neck. This prevents the escape of air or liquid

Because the effects or damage that result from an

while the cap is in position. When the cooling system

improperly maintained cooling system usually occur

pressure reaches a predetermined point, the cap valve

gradually, this system is often times neglected.

opens and will again close when the pressure drops

However, the cooling system must be treated with the

below the predetermined point.

same attention to maintenance as is given such other

systems as fuel, ignition and lubrication. A review of the

cooling system's function will show this more clearly.

In general the circulation of water through the cooling

system relies entirely upon the water pump. The water

pump draws water from the radiator and force s it

through the water jackets and cylinder head. There it

accumulates heat. Then the water flows to the upper

radiator tank and down through the radiator core, being

cooled by air from the fan. This process of removing

heat from water as it circulates holds the engine to its

most efficient operating temperature.

The following paragraphs point out several facts

about cooling system components, The affects of cooling

system neglects and procedures to be followed for

cooling system maintenance. Trouble Shooting helps

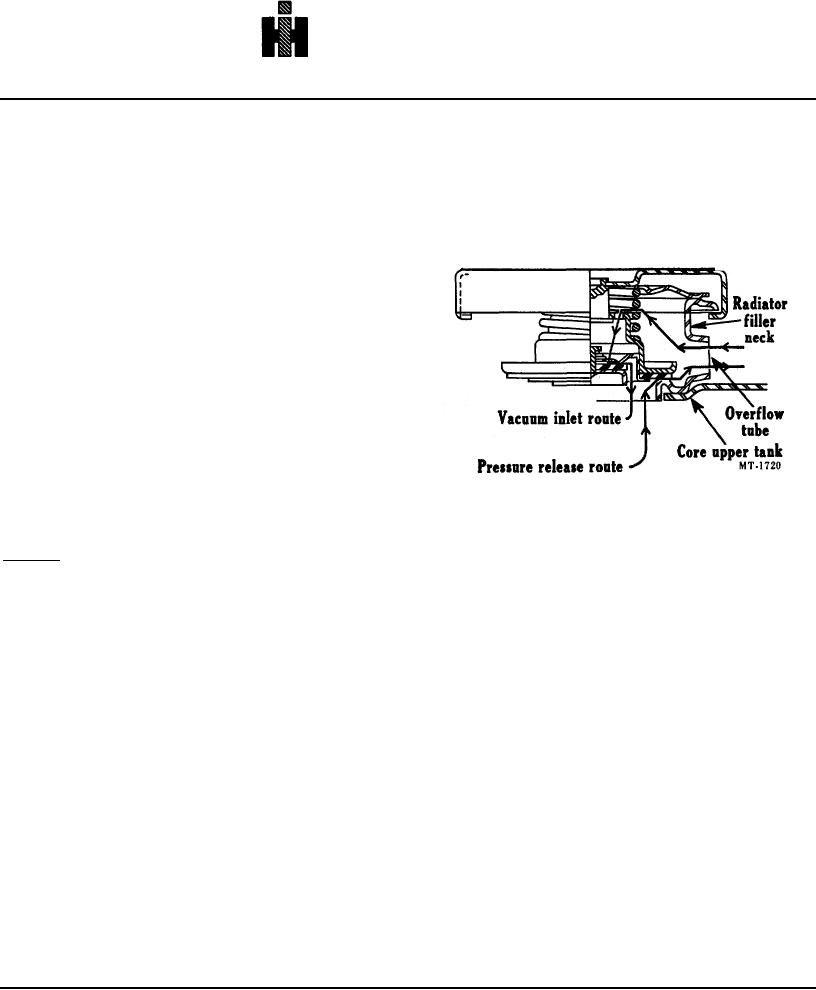

Fig. 1 Radiator Cap (Pressure Type)

have also been prepared.

COOLING SYSTEM COMPONENTS

When removing the pressure type cap from the

Radiator

radiator, perform the operation in two steps. Loosening

This component which is one of the most important

the cap to its first notch raises the valve from the gasket

in the cooling system is made up of the following parts:

and releases the pressure through the overflow pipe. In

1. Top and bottom tank look for leaks, particularly

the first stage position of the cap it should be possible to

where tank is soldered to core. Vibration and

depress the cap approximately 1/8". The prongs on the

pulsation from pressure can fatigue soldered

cap can be bent to adjust this condition. Care must be

seams.

taken that the cap is not too loose as this would prevent

2. Filler neck the sealing seat must be smooth and

proper sealing.

clean. Cams on filler neck must not be bent or

CAUTION: When removing the cap, loosen it slowly

worn so as to allow loose fitting cap. Make sure

and then pause a moment. This will avoid possible

overflow tube is not plugged.

burning by hot water or steam. Continue to turn the cap

3. Radiator cap is the pressure sealing type. Its

to the left until you can remove it.

purpose is to hold the cooling system under a

4. Tubes because the se are very small they can

slight pre s sure, increasing the boiling point of

become easily clogged, or partially so, by rust

the cooling solution and preventing loss of

and scale. The general condition of cooling

solution due to evaporation and overflow.

system and operating temperature are

The cap (Fig. 1) has a spring-loaded valve, the seat

indications as to whether or not tube s are clean.

of which is below the overflow pipe in

Another good test is to feel core for cold spots.

5. Fins these thin metal sheets radiate or pass off

heat picked up by tubes. They should be kept

free of bugs, leaves, straw, etcetera so as to

allow the free passage of air. Bent fins should

be straightened.

239