MOTOR TRUCK SERVICE MANUAL

COOLING SYSTEM

GENERAL

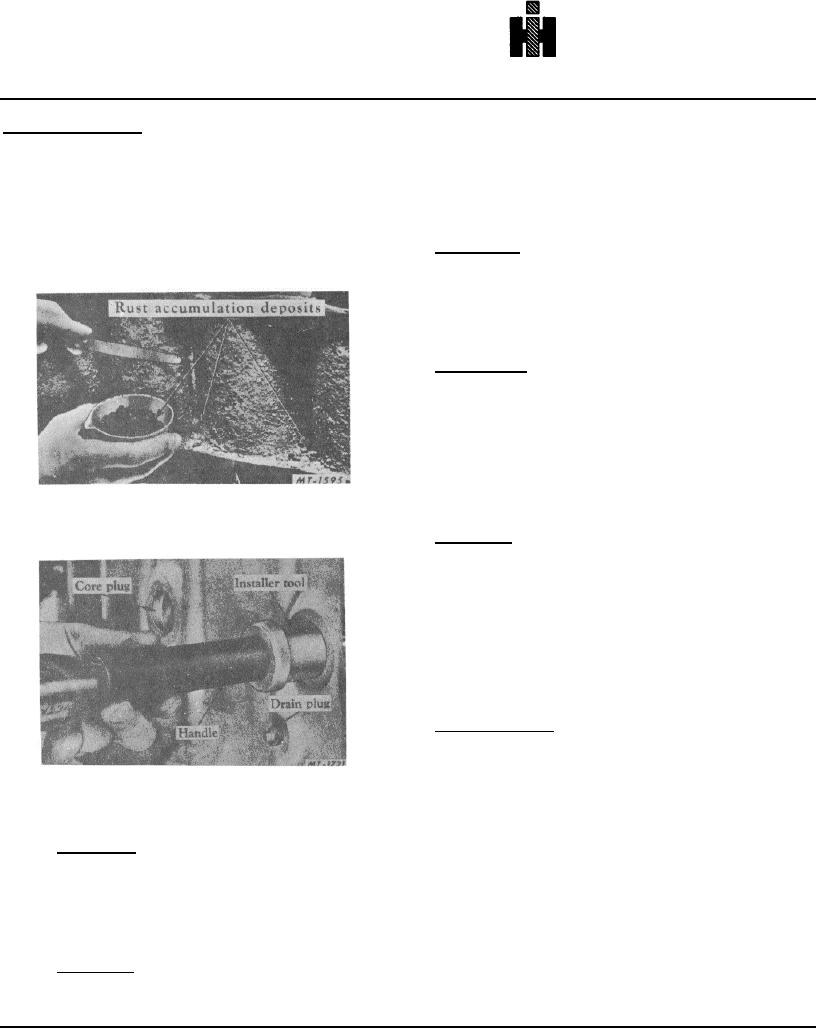

Engine Water Jacket

3. Gaskets must be in good condition to prevent

The water jacket permits coolant to be circulated

both internal and external leaks. If there are

around the cylinder walls, combustion chamber, and

external leaks around gaskets, there may also

valve assemblies. Some of these coolant passages are

be internal leaks into engine. Proper tightening

small and can easily become clogged if cooling system

of the head bolts with a torque wrench is

does not receive the proper maintenance. Figure 2

essential for preventing leaks around head

illustrates how rust and scale deposits will accumulate

gasket.

inside the water jacket on an engine that has been

Water Pump

The water pump which circulates coolant through the

neglected.

cooling system is likewise a most essential part. The

pump should be checked carefully for leaks and proper

lubrication, and if leaking, cracked or in bad condition, it

should be rebuilt or replaced promptly. For rebuild of

water pump, see Engine Section.

Fan and Belts

The fan should be checked for loose or bent blades.

A loose blade might work free during operation and

cause damage. A bent blade will reduce the fan's

efficiency.

Fan belts must be adjusted for proper tension. A

belt adjustment that is just tight enough to prevent

slipping on pulleys maybe considered a proper

adjustment. A tight belt adjustment is to be avoided

Fig. 2 Cross Section of Engine Shoving Cooling System

Neglect.

Thermostat

Thermostats used in H trucks are of the non-

adjustable-type and are incorporated in the cooling

system for the purpose of retarding or restricting the

circulation of coolant during engine warm-up.

Engine overheating and loss of coolant is some

times due to an inoperative thermostat. To check for this

condition, remove thermostat and test by submerging in

hot water and noting temperature at which thermostat

opens or closes. Use an accurate high temperature

thermometer for making this test.

Hose and Clamps

Hoses and their connections must be checked

regularly because they are often the source of hidden

trouble. Hose can oftentimes appear in good condition

on the outside while the inside will be partially

Fig. 3 Installing Core Plug Using SE1725 Installer Tool

deteriorated. If there are any doubts about a hose doing

with SE1581B Handle.

its job, replacement should be made. The clamps

should be inspected to make sure they are strong

1. Core plugs these are sometimes mistakenly

enough to hold a tight connection.

called freeze plugs.

They do not provide

protection against freezing expansion but are

only pre sent because of engine block casting

methods. Remove and replace core plugs that

show signs of leaking or rusting through Use

installing tool for core plug replacement (Fig. 3).

2. Drain plugs the water jacket of each engine has

one or more drain plugs. These should receive

seasonal care and kept free of rust and scale.

240