BRAKES-PARKING MOTOR TRUCK SERVICE MANUAL

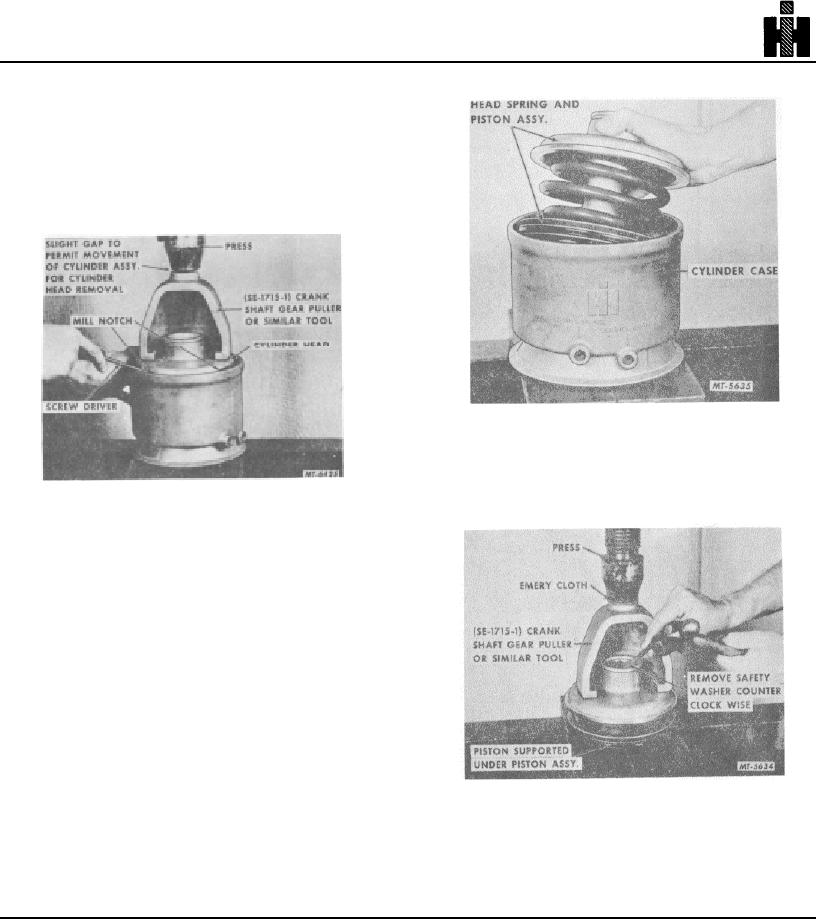

tion, use a soft hammer to bump the head carefully to

loosen since head may be stuck in place by foreign

material, sealer, or corrosion. If difficulty in removing

head is still experienced, use the three mill notches

equispaced around the cylinder head for prying head

from cylinder case (Fig. 12). Use a screwdriver or

similar tool carefully at each notch in turn so that cylinder

head does not become cocked.

Fig. 13 Removing Head, Spring and Piston Assembly

When cylinder head is free, slowly release press

gradually and remove cylinder head, spring and piston

assembly from cylinder case (Fig. 13).

Fig. 12 Using Screwdriver to Loosen Cylinder Head

CAUTION: If spring brake unit has a damaged

piston, the spring is no longer restricted when snap ring

is removed. This could allow cylinder head to be

forcefully expelled. When this condition exists or when

there is doubt as to the spring being restricted, always

use a tool similar to a crank shaft gear puller (SE17151).

On early production spring brake cylinder heads

(where no notches were provided) the cylinder head can

be reworked to include these notches. When making

this modification, be careful to avoid cutting through the

cylinder head wall. While there is no air pressure under

the spring brake cylinder head, any notch inadvertently

cut through the head would allow dirt or moisture to enter

and cause damage to internal parts.

It should be further emphasized that the addition of

notches to the cylinder head does not lessen the need

Fig. 14 Loosening Safety Washer.

for the safety precautions previously pointed out. Always

10. In order to dissemble the head, spring and piston

mount spring brake assembly in press when

assembly, this unit must be set under a press.

disassembling.

Use a tool similar to SE17151. Fold a small

square of

233