TRUCK SERVICE MANUAL

ELECTRICAL

f.

If ampere output is within 10 percent of

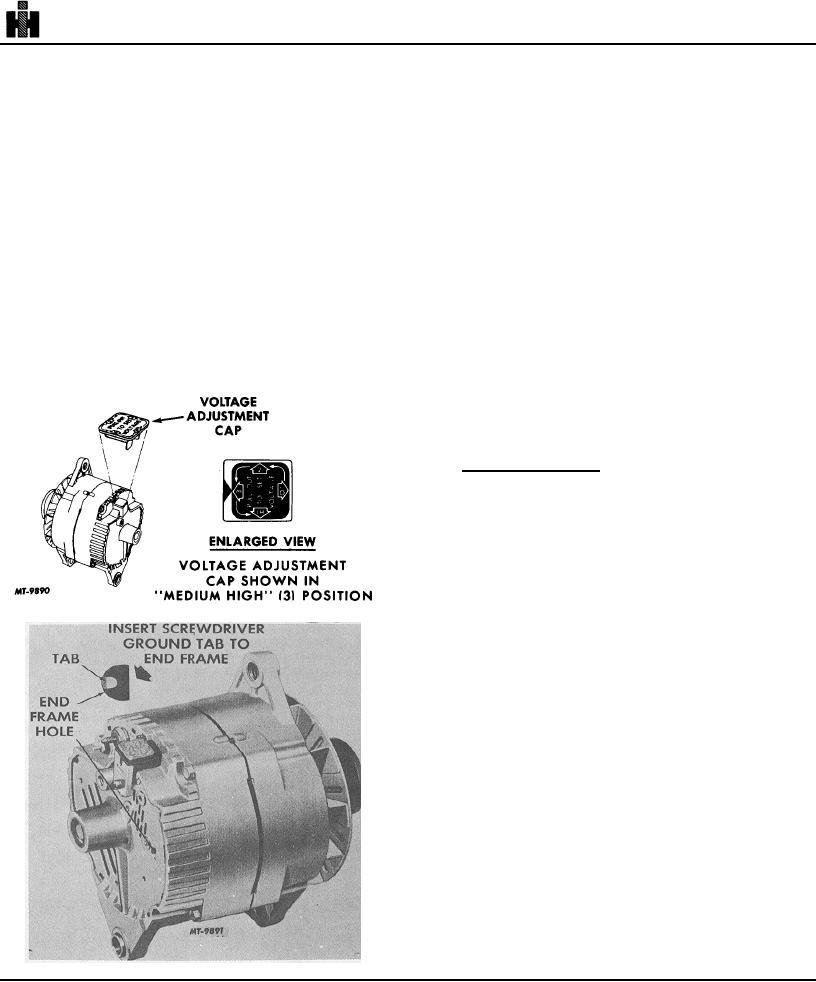

IMPORTANT: The voltage adjustment in

rated output as stamped on generator

Fig. 4 is for purposes of illustration only.

frame, integral charging system is not

The actual adjustment as shipped from the

defective. In this case, an adjustment of

factory may be in some other position

the voltage setting may correct the

depending on the application requirement.

undercharged condition. Raise the setting

g. If ampere output is not within 10 percent of

by removing the voltage adjusting cap,

rated output as stamped on integral

rotating in increments of 90 and then

charging system frame, ground the field

reinserting the cap in the connector body.

winding by inserting a screwdriver into the

As illustrated in Fig. 4, the cap is set for

test hole, Fig. 5. NOTE : Tab is within 3/4

medium high voltage. With position 2

inch of casting surface. Do not force

aligned with the arrow, the setting is

screwdriver deeper than one inch into end

medium low; position "LO" is low, and

frame.

position "HI" is the highest regulator setting.

h. Operate engine at moderate peed as

After adjusting the setting, check for an

required and adjust carbon pile as required

improved energizer condition after a service

to obtain maximum current output.

period of reasonable length, such as one

i.

If output is within 10 percent of rated output,

week.

replace regulator and check field winding.

j.

If output is not within 10 percent of rated

output, check the field winding, diode trio,

rectifier bridge and stator.

accessories off.

B. Overcharged Battery

1. Check the battery.

2. If battery is not defective or overheated, connect

a voltmeter between No. 2 terminal to ground. If

reading is zero, No. 2 lead circuit is open.

3. If battery and No. 2 lead circuit check good, but

an obvious overcharge condition exists as

evidenced by excessive battery water usage,

Fig. 4

proceed as follows:

a. Separate end frames as covered in

"DISASSEMBLY." Check field winding for

shorts. If shorted, replace rotor and

regulator.

b. Connect ohmmeter using lowest range

scale from brush lead clip to end frame as

shown in Step 1, Fig. 6; then reverse lead

connections.

c. If both readings are zero, either the brush

lead clip is grounded or regulator is

defective.

Fig. 5

254