ELECTRICAL

TRUCK SERVICE MANUAL

d. A grounded brush lead clip can result from

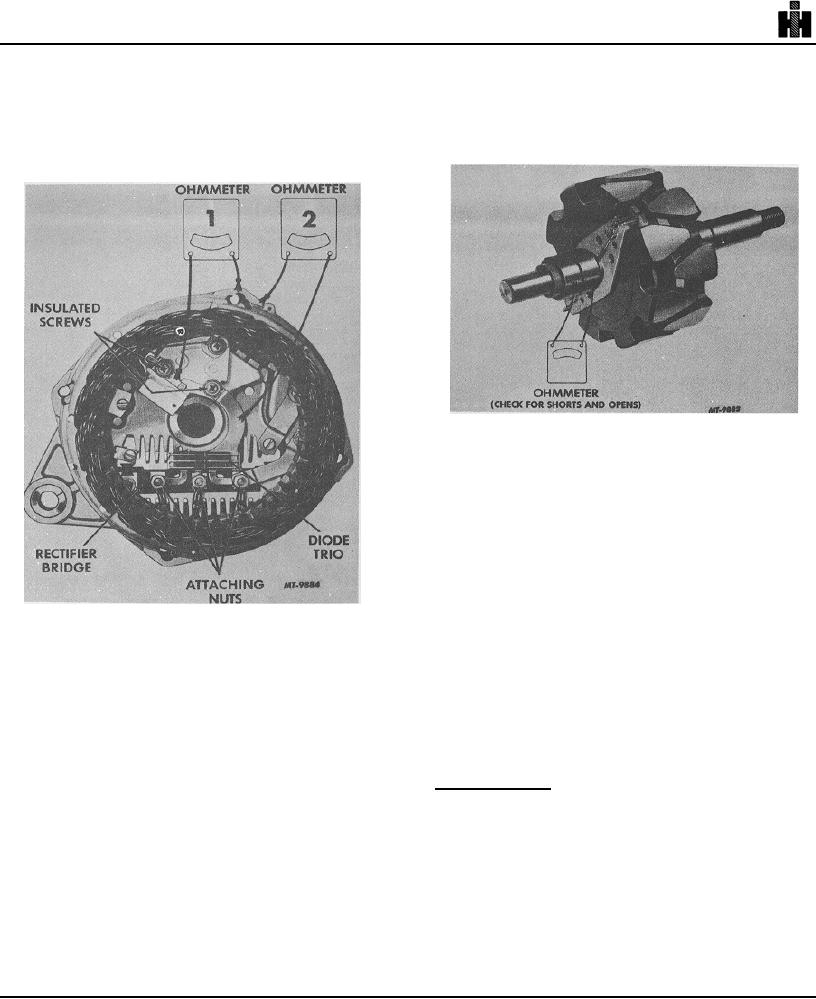

Rotor Field Winding Checks

omission of insulating washer, Fig. 6,

omission of insulating sleeve over screw, or

To check for opens, connect the test lamp or

damaged insulating sleeve. Remove screw

ohmmeter to each slip ring. If the lamp fails to light or if

to inspect sleeve. If satisfactory, replace

the ohmmeter reading is high (infinite), the winding is

regulator as covered under "Brush Holder

open, Fig. 7.

and Regulator Replacement. "

Fig. 7

The winding is checked for short circuits or

excessive resistance by connecting a battery and

ammeter in series with the edges of the two slip rings.

An ammeter reading above the specified value indicates

shorted windings; a reading below the specified value

indicates excessive resistance. If the winding is shorted,

replace the rotor and the regulator as covered in "Brush

Holder and Regulator Replacement."

An alternate method is to check the resistance of the

field by connecting an ohmmeter to the two slip rings,

Fig. 6

Fig. 7. If the resistance reading is below the specified

DISASSEMBLY

value, the winding is shorted; if above the specified

value, the winding has excessive resistance. The

1. Remove four thru-bolts from drive end frame.

specified resistance value can be determined by dividing

the voltage by the current. Remember that the winding

2. Separate slip ring end frame and stator assembly

resistance and ammeter reading will vary slightly with

from drive end frame and rotor assembly.

winding temperature changes.

3. Separate stator from end frame by removing three

Diode Trio Check

stator lead attaching nuts.

The diode trio is identified in Fig. 6. To check the

4. Place tape over bearing and shaft to protect from

diode trio, remove it from the end frame assembly by

dirt. Use pressure-sensitive tape and not friction

detaching the nuts and attaching screw. Connect an

tape, which would leave a gummy deposit.

ohmmeter having a 11/2 volt cell and using the lowest

range scale to the single connector and to one of the

5. Inspect all leads for burned connections or opens,

three connectors, Fig. 8. Observe the reading. Then

and brushes for excessive wear. Inspect springs for

reverse the ohmmeter leads to the same two connectors.

distortion or discoloration. Replace as required.

If both readings are the same, replace the diode trio. A

Clean brushes with a soft, dry cloth if they are to be

good diode trio will give one high and one low reading.

reused. During servicing and reassembly hold

Repeat this same test between the single connector and

brushes and springs in holder with a pin or toothpick

inserted through end frame hole.

255