TRUCK SERVICE MANUAL

ENGINE

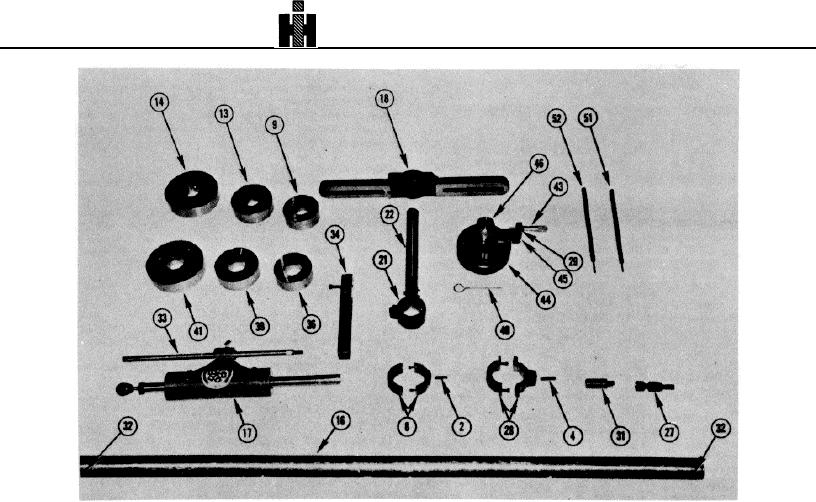

2.

Cutting Tool

17.

Bore Feed Assembly

31.

Drive Adapter

43.

Micrometer i

4.

Cutting Tool

18.

Bore Bar Bridge

32.

Capscrew

44.

Micrometer Base

8.

Cutter Holder

21.

Bearing Bridge

33.

Torsion Bar

45.

Micrometer Bracket

9.

Checking Ring

22.

Bearing Bar

34.

Bracket

46.

Micrometer Shaft

13.

Checking Ring

27.

Swivel Joint

36.

Centering Ring

49.

Cutter Pin

14.

Checking Ring

28.

Cutter Holder

39.

Centering Ring

51.

Allen Wrench

16.

Bore Bar

29.

Capscrew

41.

Centering Ring

52.

Allen Wrench

Fig. 1-16, (ST-1177). Exploded view of ST-1177 Boring Tool

2. Coat outside of sleeve lightly with a suitable sealant

ASSEMBLY TO BLOCK

and drive sleeve into bore with driver until it bottoms (see ST-

1. Remove two undamaged main bearing caps.

1168-36 through 46). A solid sound can be heard when

Preferably one from each end of block or as far apart as

sleeve bottoms.

possible.

3. The sleeve will protrude above the top of block by

2. Insert proper centering rings, with oiler up, in two bores

0.004 inch [0.10 mm] and must be filed even with the top of

and tap top of centering ring with plastic hammer to seat.

block. Remove all burrs with emery cloth.

3. Reinstall main bearing caps and torque to required

4. The salvage sleeve is designed to be 0.005 to 0.010

specifications, following steps in Table 1-1 (18).

inch [0.13 to 0.25 mm] above required counterbore depth.

Note: If centering ring must be installed in journals which

Check depth and cut to specifications listed in Table 1-1 (2).

have had caps replaced by semi-finished caps, limit torque to

ST-1177 Main Bearing Boring Tool

10 ft-lbs [1. kg m].

This tool is designed to perform both the boring and checking

4. Oil centering ring bores and boring bar, install boring

functions.

Before boring operation, allow tool and block

bar

to stabilize to room temperature.

347